When people first hear about spray drying, one of the most common questions they ask is: “Does spray drying use heat?”

The answer is yes — but the way heat is applied in the spray drying process is both controlled and efficient, designed to remove moisture rapidly without damaging the product.

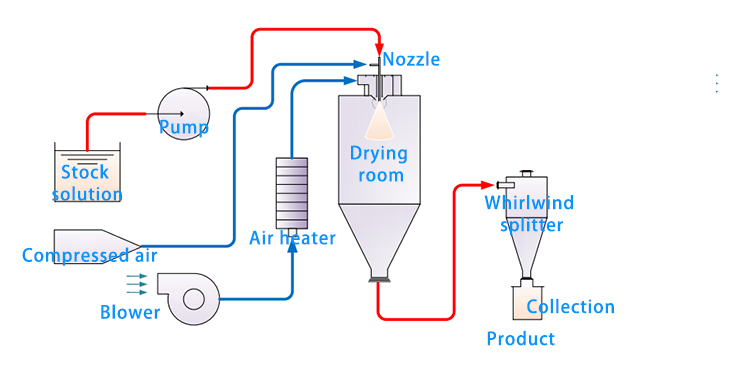

Spray drying is a thermal drying process that converts a liquid or slurry into a dry powder in seconds. The process begins when the liquid feed — such as milk, herbal extract, pharmaceutical solution, or cosmetic emulsion — is atomized into tiny droplets inside a spray drying chamber.

These droplets are then exposed to a stream of hot air, which instantly evaporates the moisture, leaving behind fine, dry particles that are collected as powder.

While heat is essential, temperature control is the heart of the process.

A well-designed spray dryer — like the OLLITAL Laboratory Spray Dryer (OLT-SD Series) — maintains precise inlet and outlet temperatures to ensure efficient drying while protecting sensitive materials. For example, the inlet air temperature may reach 150–200°C, but the product temperature remains much lower, usually below 100°C, because the evaporation of moisture cools the particles immediately.

This makes spray drying suitable even for heat-sensitive materials such as enzymes, probiotics, vitamins, and cosmetic active ingredients.

The use of heat in spray drying provides several key benefits:

Rapid Drying: The combination of fine droplets and hot air ensures extremely fast moisture removal.

Uniform Powder Quality: Controlled heat produces consistent particle size and improved solubility.

Enhanced Stability: By quickly transforming liquids into stable powders, spray drying extends product shelf life.

Scalability: From lab-scale to industrial-scale systems, the same heat-based principle ensures predictable, repeatable results.

At Xiamen OLLITAL Technology Co., Ltd., our spray dryers are widely used in pharmaceutical, food, chemical, and cosmetics industries. Each system is engineered for precise heat control and easy operation, allowing researchers and manufacturers to handle a variety of materials — from milk powder and herbal extracts to cosmetic emulsions and ceramic suspensions.

Our OLT-SD-10L and OLT-SD-20L models are ideal for pilot-scale production, while the OLT-Mini Spray Dryer is perfect for laboratory research that requires tight control over drying temperature and particle characteristics.

So, does spray drying use heat? Absolutely — but in a smart and controlled way.

The heat enables quick moisture removal without overheating the material, producing high-quality powders with excellent stability and appearance. With precise temperature management and advanced design, OLLITAL spray dryers make it possible to achieve outstanding drying results across multiple industries.

If you’re exploring efficient and reliable drying solutions, contact Xiamen OLLITAL Technology Co., Ltd. to learn how our advanced spray dryers can optimize your production process.