It is widely used in petroleum, chemical, pharmaceutical, materials, metallurgy and other fields. Such as catalytic reaction, polymerization reaction, supercritical reaction, high temperature and high pressure synthesis, hydrogenation reaction, etc.

There are three types of multi position parallel reactors: A, B and C.

Item no.:

OLT-PX seiresCapacity:

50-1000mlVoltage:

220V 50HzCertificate:

CE CertificateWarranty:

1 yearThe multi position parallel reactor is an upgraded and integrated product of the basic model, which greatly saves the space resources of the laboratory. This type of reactor is mainly used in laboratory parallel tests, constant variable comparative analysis tests, etc. It is widely used in petroleum, chemical, pharmaceutical, materials, metallurgy and other fields. Such as catalytic reaction, polymerization reaction, supercritical reaction, high temperature and high pressure synthesis, hydrogenation reaction, etc.

There are three types of multi position parallel reactors: A, B and C.

A type

Main functional features

1. Multiple parallel integrated design, saving floor space

2. Multi station parallel design, convenient for constant variable analysis and condition selection

3. Each station can be controlled independently, and the user can customize the reaction conditions

4. The kettle body and the heating furnace can be separated quickly

5. Magnetic stirring or mechanical stirring can be selected according to customer requirements

6. PLC + touch screen or computer control, can control and collect temperature, pressure, speed and other data and form historical trend curve. All data can be stored and exported. The user can define the upper limit of temperature and pressure, and it has over temperature and over pressure alarm chain to ensure the safety of the experiment.

7. Each station can be equipped with functions such as centralized air intake and exhaust, process sampling, built-in cooling coil, isobaric feeding and condensation reflux recovery according to user requirements

Speicifcation

| Model | OLT-PXA4-250FJ |

| Position | 4 stations, which can be customized according to specific requirements |

| Capacity | 50ml\100ml\250ml\500ml |

| Material | Standard configuration 316L, can be customized Hastelloy, Monel, titanium, etc |

| Temperature | Usage temperature: RT-300℃, Desigh temperature: RT-350℃ |

| Heating method | Electric heating |

| Pressure | Usage pressure: 10Mpa, Design pressure: 12.5Mpa |

| Sealing form | Flange structure / quick opening structure / one key quick opening structure |

| Stirring form | Either magnetic stirring or mechanical stirring |

| Kettle cover interface | Mixing port *1, air inlet *1, exhaust port *1, temperature measuring port *1, pressure gauge explosion-proof disc port *1. Can be adjusted according to custom requirements |

| Control mode | PLC + touch screen or computer control |

| Extended function (optional) |

Temperature, pressure, material, process sampling, process feeding, condensation, built-in cooling coil, various functions can be customized |

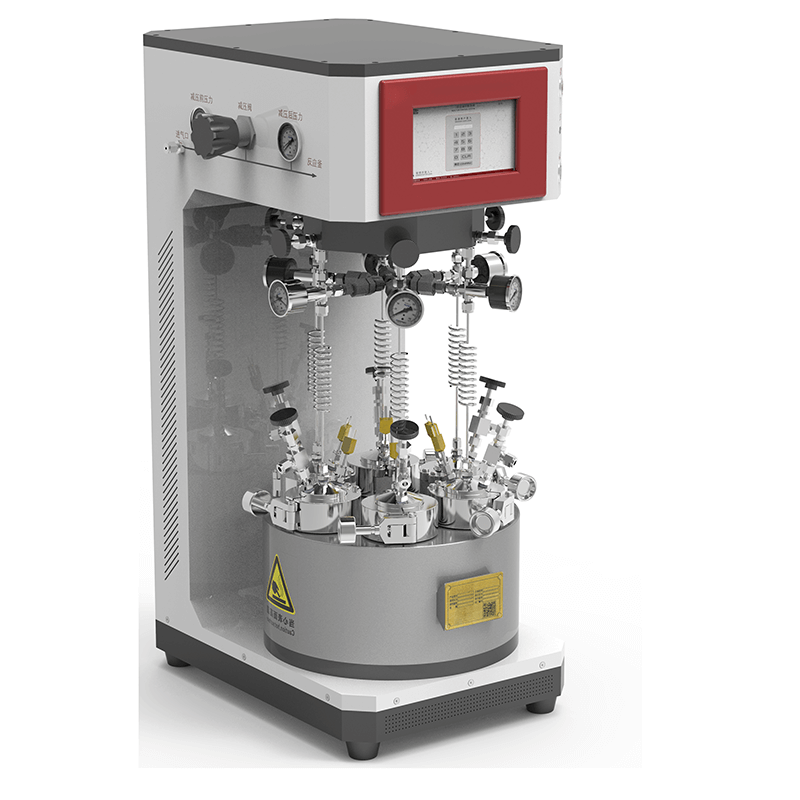

B type

Main functional features

1. Surrounding design, more saving the floor space

2. Multi station parallel design, convenient for constant variable analysis and condition selection

3. Each station can be controlled independently, and reaction conditions can be customized

4. The kettle body and heating furnace can be separated quickly

5. The pressure reducing valve can be configured for centralized air intake, and each station can be cut off separately

6. PLC + touch screen can control and collect temperature, speed and other data and form historical trend curve. The data can be stored and exported. The user can define the upper limit of temperature and pressure, and it has over temperature and over pressure alarm interlock to ensure the safety of the experiment.

Speicifcation

| Model | OLT-PXB4-100YC |

| Position | 6 stations max, which can be customized according to specific requirements |

| Capacity | 50ml\100ml\250ml |

| Material | Standard configuration 316L, can be customized Hastelloy, Monel, titanium, etc |

| Temperature | Usage temperature: RT-300℃, Desigh temperature: RT-350℃ |

| Heating method | Electric heating |

| Pressure | Usage pressure: 10Mpa, Design pressure: 12.5Mpa |

| Sealing form | One key quick opening structure |

| Stirring form | Magnetic stirring |

| Kettle cover interface | Mixing port *1, air inlet *1, exhaust port *1, temperature measuring port *1, pressure gauge explosion-proof disc port *1. Can be adjusted according to custom requirements |

| Control mode | PLC + touch screen or computer control |

| Dimension |

350*500*860mm |

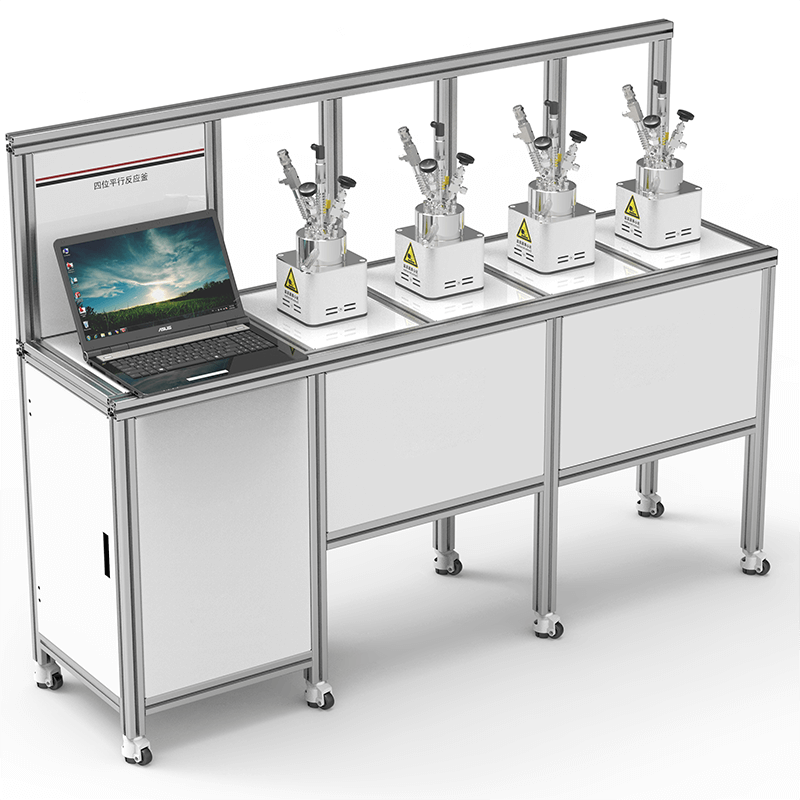

C type

Main functional features

1. Frame design, bottom universal wheel, flexible and convenient movement

2. Multi station parallel design, convenient for constant variable analysis and condition selection

3. Each station can be controlled independently, and the user can customize the reaction conditions

4. The kettle body and the heating furnace can be separated quickly

5. Magnetic stirring or mechanical stirring can be selected according to customer requirements

6. PLC + touch screen or computer control, can control and collect temperature, pressure, speed and other data and form historical trend curve. All data can be stored and exported. The user can define the upper limit of temperature and pressure, and it has over temperature and over pressure alarm chain to ensure the safety of the experiment.

7. Each station can be equipped with functions such as centralized air intake and exhaust, process sampling, built-in cooling coil, isobaric feeding and condensation reflux recovery according to user requirements

Speicifcation

| Model | OLT-PXC4-250FJ |

| Position | 4 stations, which can be customized according to specific requirements |

| Capacity | 50ml\100ml\250ml\500ml, customize |

| Material | Standard configuration 316L, can be customized Hastelloy, Monel, titanium, etc |

| Temperature | Usage temperature: RT-300℃, Desigh temperature: RT-350℃ |

| Heating method | Electric heating |

| Pressure | Usage pressure: 10Mpa, Design pressure: 12.5Mpa |

| Sealing form | Flange structure / quick opening structure / one key quick opening structure |

| Stirring form | Either magnetic stirring or mechanical stirring |

| Kettle cover interface | Mixing port *1, air inlet *1, exhaust port *1, temperature measuring port *1, pressure gauge explosion-proof disc port *1. Can be adjusted according to custom requirements |

| Control mode | PLC + touch screen or computer control |

| Extended functions |

Temperature, pressure, material, process sampling, process feeding, condensation, built-in cooling coil, various functions can be customized |

Tags :