Spray dryer is a kind of drying equipment widely used in food, pharmaceutical, chemical and other industries. It can quickly dry liquid raw materials into powder products. Spray drying technology has become an indispensable part of modern industrial production due to its advantages such as high efficiency, uniformity and controllability. This article will introduce the definition, working principle, components, application fields, advantages and precautions of spray dryer in detail.

1. Definition of Spray Dryer

Spray dryer is a device that uses spraying to spray liquid materials into droplets through high-speed centrifugal or high-pressure nozzles, and evaporates water instantly when in contact with hot air, eventually forming a powder or granular dry product. This drying method can complete large-area liquid evaporation in a short time, and is particularly suitable for drying heat-sensitive materials.

2. Working principle of spray dryer

2.1 Basic process of spray drying

The basic process of spray drying can be divided into the following steps:

- Pretreatment of liquid raw materials: pre-treat the liquid raw materials to be dried to ensure that they have suitable fluidity and uniformity.

- Atomization: spray the liquid raw materials into fine droplets through high-speed centrifugal nozzles or high-pressure nozzles. The size and uniformity of the droplets have an important impact on the quality of the final product.

- Hot air contact: hot air enters from the top or bottom of the drying tower and fully contacts the droplets. The temperature and flow rate of hot air have a direct impact on the drying effect.

- Water evaporation: the droplets quickly evaporate water in the hot air to form solid particles. During the evaporation process, the hot air takes away the water, and the dry product gradually falls to the bottom of the drying tower.

- Separation and collection: the dry product is separated and collected by devices such as cyclone separators or bag dust collectors to obtain the final dry powder product.

2.2 Key equipment and components

The main components of the spray dryer include:

- Spray device: including two types of high-speed centrifugal nozzles and high-pressure nozzles, which are used to spray liquid raw materials into droplets. High-speed centrifugal nozzles throw liquid raw materials into droplets through high-speed rotation, while high-pressure nozzles spray liquid raw materials into droplets through high-pressure pumps.

- Drying tower: The main reaction chamber of spray drying, usually cylindrical or conical structure. Hot air and droplets are fully in contact in the tower to complete the water evaporation process.

- Hot air system: including hot air furnace, air heater and fan and other devices, used to provide hot air required for drying. The temperature and flow rate of hot air need to be precisely controlled to ensure the drying effect.

- Separation and collection device: including cyclone separator, bag dust collector, etc., used to separate the dried product from the exhaust gas and collect the dry powder product.

- Control system: Modern spray dryers are usually equipped with advanced automatic control systems, which can monitor and adjust various parameters in the drying process in real time to ensure the stability of the production process and product quality.

2.3 Factors affecting the drying effect

The effect of spray drying is affected by multiple factors, mainly including:

- Characteristics of liquid raw materials: The concentration, viscosity and fluidity of liquid raw materials will affect the atomization effect and drying efficiency. Pretreatment and adjustment are required according to the specific characteristics of the raw materials.

- Droplet size and uniformity: The size and uniformity of the droplets directly affect the drying speed and product quality. It is usually required that the finer the droplets, the faster the drying speed and the more uniform the product particles.

- Hot air temperature and flow rate: The temperature and flow rate of hot air have a direct impact on the evaporation rate of water and the drying efficiency. It needs to be optimized and adjusted according to the specific process requirements.

- Structural design of the drying tower: The structural design of the drying tower affects the contact time and contact area between the hot air and the droplets, thereby affecting the drying effect. Reasonable airflow distribution in the tower and material flow path design are the key.

3. Application fields of spray dryers

3.1 Food industry

Spray dryers are widely used in the food industry, for example:

- Milk powder production: fresh milk or whey liquid is dried into milk powder through a spray dryer to maintain the nutritional content and taste of dairy products.

- Fruit and vegetable powder production: the juice or mud of fruits and vegetables is dried into powder through a spray dryer, which is used to make fruit and vegetable beverages, fruit and vegetable slices and other products.

- Protein powder production: protein solution is dried into protein powder through a spray dryer, which is used in the fields of health care products and food additives.

3.2 Pharmaceutical industry

The application of spray dryers in the pharmaceutical industry mainly includes:

- Drug preparation production: drug solution or suspension is dried into powder through a spray dryer, which is used to prepare tablets, capsules and other drug preparations.

- Traditional Chinese medicine extract production: traditional Chinese medicine extract is dried into traditional Chinese medicine powder through a spray dryer, which is used in the production of traditional Chinese medicine preparations and health care products.

3.3 Chemical industry

The application of spray dryers in the chemical industry includes:

- Catalyst production: catalyst solution is dried into powder through a spray dryer, which is used as a catalyst in chemical reactions.

- Pigment production: Pigment solution or suspension is dried into pigment powder through a spray dryer for use in products such as coatings and inks.

3.4 Other applications

Spray dryers are also widely used in ceramics, minerals, pesticides, feed and other fields to meet the drying needs of various materials.

4. Advantages of spray dryer

4.1 Efficient drying

The spray dryer can complete large-area liquid evaporation in a short time, with high drying efficiency, and is particularly suitable for continuous drying of large amounts of liquid materials.

4.2 Uniform products

By precisely controlling the atomization process and drying conditions, the spray dryer can produce dry powder products with uniform particles and stable quality, meeting high quality requirements.

4.3 Applicable to heat-sensitive materials

During the spray drying process, the contact time between droplets and hot air is short, which can effectively avoid thermal degradation of heat-sensitive materials and maintain the activity and nutritional content of the materials.

4.4 Strong controllability

Modern spray dryers are equipped with advanced automatic control systems that can monitor and adjust various parameters in real time, achieve precise control of the drying process, and ensure the stability of the production process and product quality.

5. Precautions for spray dryer

5.1 Material pretreatment

Before spray drying, the liquid raw materials need to be fully pretreated to ensure that they have appropriate fluidity and uniformity. Filtering, homogenization, blending and other treatments are required according to the specific material characteristics.

5.2 Operating specifications

Operators need to receive systematic training to master the correct operation methods and emergency handling capabilities of the spray dryer. The operating procedures must be strictly during the production process to ensure the safety of equipment and personnel.

5.3 Equipment maintenance

Maintenance of the spray dryer is the key to ensuring the long-term stable operation of the equipment. It is necessary to regularly check and clean the spray device, drying tower, hot air system and other components to ensure the normal operation and production efficiency of the equipment.

5.4 Environmental protection measures

A certain amount of waste gas and wastewater will be generated during the spray drying process, and effective environmental protection measures need to be taken to treat them. The impact on the environment can be reduced by installing waste gas purification devices and wastewater treatment systems.

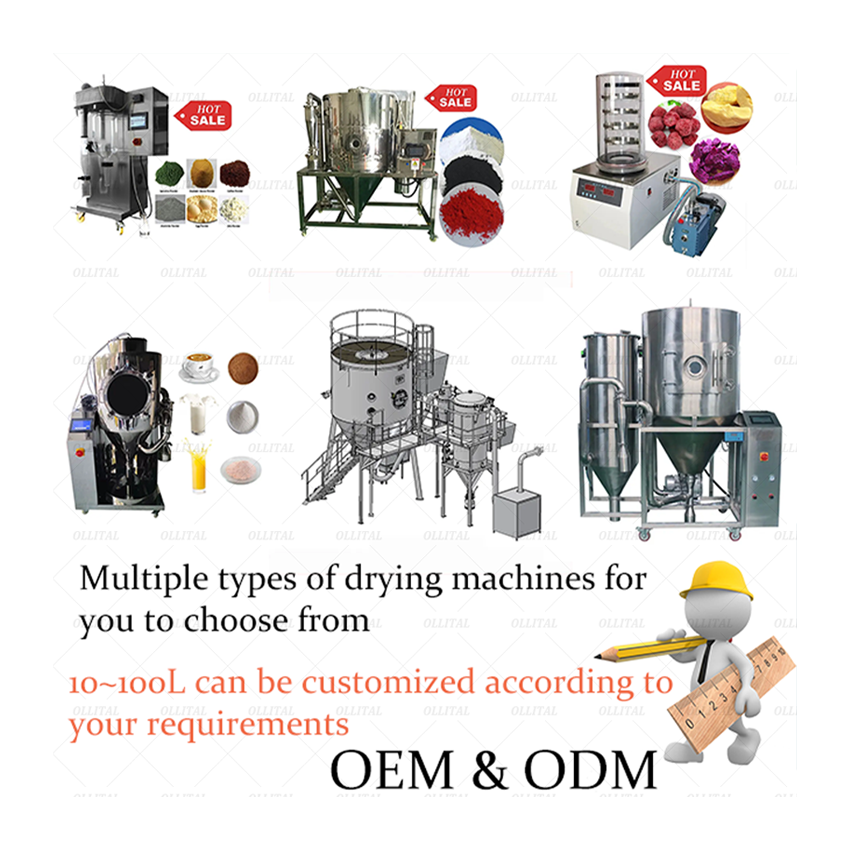

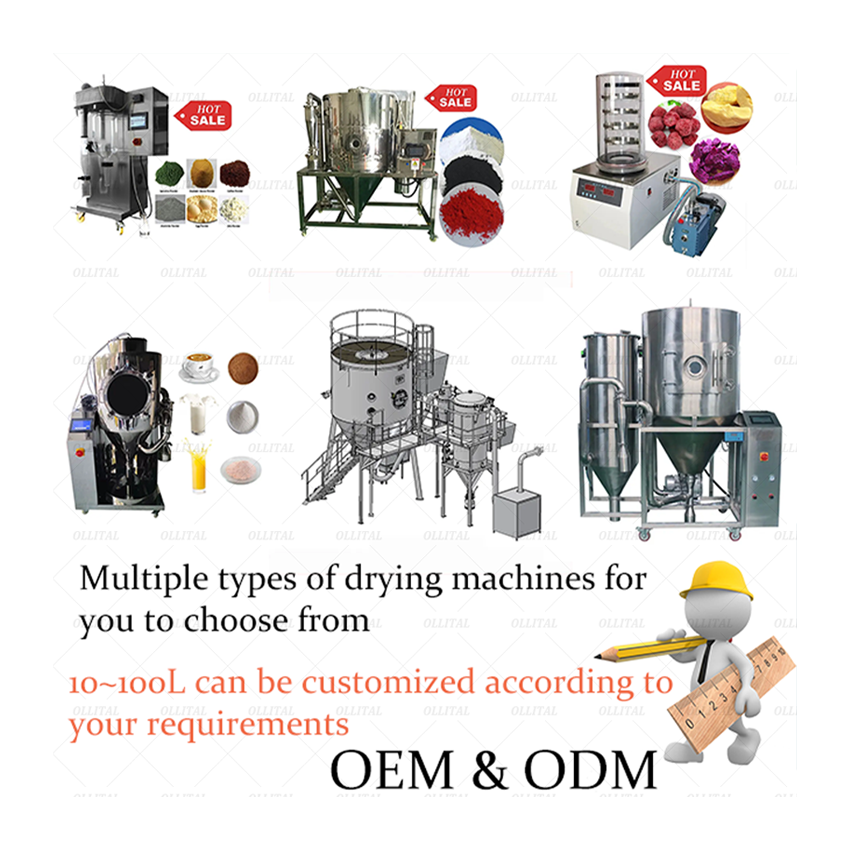

6. Our spray drying equipment

6.1 Company Profile

Our company is committed to providing high-quality spray drying equipment, with many years of industry experience and a professional technical team. We focus on product research and development and innovation, and continuously improve the performance and reliability of the equipment to meet the diverse needs of customers.

6.2 Product advantages

- Advanced technology: Our spray drying equipment adopts advanced atomization technology and control system, which can achieve efficient and uniform drying effect.

- High-quality materials: The main components of the equipment are made of corrosion-resistant and high-strength materials to ensure the long-term stable operation of the equipment.

- Flexible customization: According to the specific needs of customers, we can provide spray drying equipment of different specifications and configurations to meet the requirements of different materials and production scales.

- Perfect service: We provide a full range of pre-sales consultation, technical support and after-sales service to ensure that customers have no worries during the use of the equipment.

6.3 One-stop solution

Our company not only provides spray drying equipment, but also provides a full set of solutions such as material pretreatment and drying post-treatment. We are committed to providing customers with one-stop supporting services in the dry ice industry, from equipment selection, installation and commissioning to operation training and maintenance, to ensure that customers can produce efficiently and stably.

Summary

As an efficient and controllable drying equipment, spray dryer is widely used in food, pharmaceutical, chemical and other industries. By understanding the working principle and application field of spray dryer, we can better utilize this advanced technology to improve production efficiency and product quality. If you have any questions about spray dryer or need further technical support, please feel free to contact us, we will serve you wholeheartedly.