Reactor, this equipment has become an indispensable equipment in the field of industrial production and scientific research due to its excellent sealing and flexible operation mode. It has shown unparalleled advantages in dealing with complex chemical reaction processes, and can provide safe and efficient solutions both in laboratories and industrial production lines. This article will discuss in detail the detailed application of reactors in different industries and demonstrate its important role in the fields of chemical industry, food, environmental science and energy.

Common use

Organic synthesis: such as hydrogenation, oxidation, polymerization and other reactions.

Catalytic research: catalyst performance testing under high temperature and high pressure conditions.

Material preparation: synthesis of nanomaterials, polymer materials, etc.

Hydrothermal reaction: such as crystal synthesis, mineral simulation, etc.

Applications in different industries

1.Chemical Industry

The reactor is one of the core equipment in the chemical industry and is used for a variety of chemical reactions, including polymerization, nitration, hydrogenation, esterification, etc.

Organic synthesis: such as polymerization reactions for the production of plastics, rubber and fibers.

Inorganic reactions: such as chlorination reactions and acid-base neutralization reactions.

Catalytic reactions: more efficient chemical reactions with the help of catalysts.

2.Food and Beverage Industry

In the food industry, reactors are used to mix, heat and react raw materials.

Condiment production: such as the brewing of soy sauce and vinegar.

Beverage manufacturing: used for fermentation, saccharification and other processes.

Food processing: such as homogenization and sterilization of jams and dairy products.

3.Petroleum and Energy Industry

In the field of petroleum processing and energy, reactors are used to decompose and transform various organic compounds.

Oil refining: used for hydrocracking reactions to increase the yield of light oil.

Biofuels: such as converting biomass into fuel ethanol or biodiesel.

Synthesis gas preparation: such as the production of chemical raw materials such as methanol and ammonia.

4.Materials Science and Nanotechnology

Reactors are widely used in the synthesis and preparation of new materials.

Polymer materials: used to prepare polymers and composite materials.

Nanomaterials: used to prepare new materials such as carbon nanotubes and graphene.

Functional materials: such as the preparation of conductive films and optoelectronic materials.

5.Environmental Engineering

Reactors play an important role in wastewater treatment and waste gas treatment.

Sewage treatment: Reactors are used for chemical reactions such as oxidation and flocculation.

Flue gas desulfurization: used to absorb sulfur dioxide in wet desulfurization.

Solid waste treatment: solid waste is treated in pyrolysis and chemical reactions.

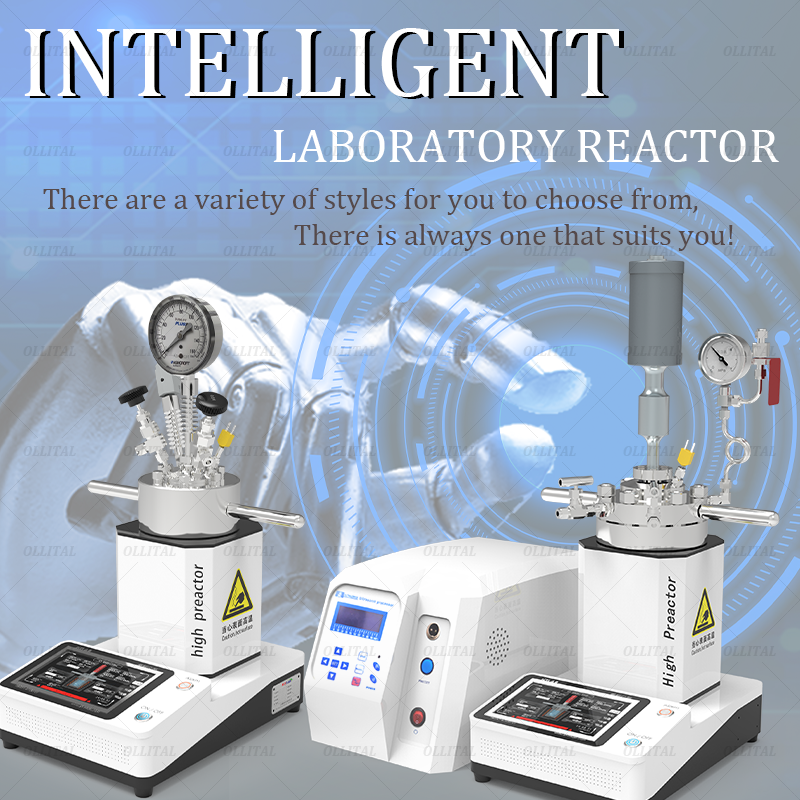

6.Scientific research and laboratories

Reactors are used as small-scale equipment in scientific research and experiments to develop new processes and verify reaction conditions.

Chemical reaction research: optimize reaction conditions such as temperature, pressure, catalysts, etc.

New process development: such as green chemistry and sustainable technology.

7.Other applications

Coatings industry: production of paints, adhesives and other products.

Fragrances and cosmetics: synthetic flavors and emulsified cosmetics.

Looking at the big picture, the reactor plays a vital role in promoting the efficient conversion of substances. It is not only widely used in various chemical reactions in industrial production, but also shows its unique value in the field of scientific research. The popularity and development of this equipment has greatly accelerated the pace of progress and innovation in modern society. By precisely controlling the reaction conditions, the reactor helps scientists realize more complex experimental ideas and provides a powerful tool for many disciplines such as medicine, chemistry, and materials. Therefore, it can be said that without technological innovations such as reactors, modern society may stagnate in the progress of certain key areas.

Reactions in the reactor

1. Polymerization reaction

Plastics: used for the synthesis of polymer materials such as polyethylene, polypropylene, and polystyrene.

Rubber: production of styrene-butadiene rubber, butadiene rubber, etc.

Fibers: synthesis of fiber materials such as polyester, nylon, and acrylic.

Typical process: polymerization of monomers into polymer materials by heating or introducing catalysts in a polymerization reactor.

2. Nitration reaction

Used for the production of explosives (such as nitroglycerin, trinitrotoluene) and nitro compounds (such as nitrobenzene).

Control the temperature and pressure in the reactor, and use concentrated nitric acid or sulfuric acid mixture for reaction.

3. Esterification reaction

Use: used to synthesize ester solvents (such as ethyl acetate, butyl acetate), plasticizers (such as phthalates).

Reaction process: organic acid and alcohol are heated in a reactor and a catalyst (such as sulfuric acid or solid acid) is added to react.

Control point: The reactor needs to be designed to efficiently recover the byproduct water in the reaction.

4. Hydrogenation reaction

Petrochemical products: used to produce methanol, ethanol, isopropanol, etc.

Organic compounds: such as hydrogenated vegetable oil, catalytic hydrodesulfurization, and synthetic amines.

In the reactor, catalysts and hydrogen are added to react under high temperature and high pressure.

Equipment features: resistant to high temperature and high pressure, equipped with a safety valve to cope with possible pressure surges.

5. Alkalization reaction

Application: used for the preparation of soaps, detergents and some organic matter (such as carboxylates).

Reaction process: neutralization reaction of acid and alkali or saponification reaction of alkali and oil.

Equipment requirements: The stirring device needs to evenly mix the materials and have strong corrosion resistance.

6. Chlorination reaction

Chlorination products: such as chloroform, chlorobenzene, PVC resin, etc.

Process characteristics: Chlorine is introduced into the reactor, and the reaction is accelerated by light or catalyst.

Precautions: Prevent chlorine leakage, and the equipment must be resistant to chlorine corrosion.

7. Addition reaction

Application: Used to produce organic compounds such as ethanolamine and epoxide.

Ethylene oxide, amine or other addition reactants are introduced into the reactor, and the conditions are strictly controlled.

8. Vulcanization reaction

Application: Used in rubber vulcanization production to improve the elasticity and durability of rubber materials.

Reactor process: Promote the chemical combination of sulfur and rubber molecules at a specific temperature and in the presence of a vulcanizing agent.

9. Oxidation reaction

Use: Used to prepare aluminum oxide, ethylene oxide, etc.

Introduce oxygen or air into the reactor to control the contact time and temperature of the reactants.

10. Rearrangement reaction

Used in organic chemistry to synthesize more complex molecular structures, such as the preparation of ketones.