[Alias]:Laboratory multifunctional extraction and concentration unit,small extraction and concentration tank,traditional Chinese medicine extraction and concentration tank,electric heating extraction and concentration tank

[Structure]: Fully enclosed

[Application range]: The Hot reflow extraction and concentration unit is suitable for normal pressure,micro pressure,decoction,warm soaking,forced circulation of heat reflow,penetration,plant essential oils,aromatic oils in traditional Chinese medicine,plants,bio-pharmacy,food,chemical industries and other industries. Various processes such as extraction and concentration of components and recovery and concentration of organic solvents. It is very suitable for trial production in universities,research institutes,laboratories of enterprises and institutions,and small and medium-sized pharmaceutical factories.

[Function]: It is composed of a dynamic extraction tank,an evaporation concentrator and a process pipeline,which integrates dynamic heat reflow extraction,vacuum concentration,and solvent recovery,and can continuously and synchronously extract and concentrate in a closed state,and produce during concentration. After condensing,the solvent vapor will be reflowed to the extraction tank,and the extracted materials can be reheated by the secondary steam,and the thermal reflow dynamic extraction can be carried out. It is suitable for the normal temperature and 60℃ Low temperature extraction around .

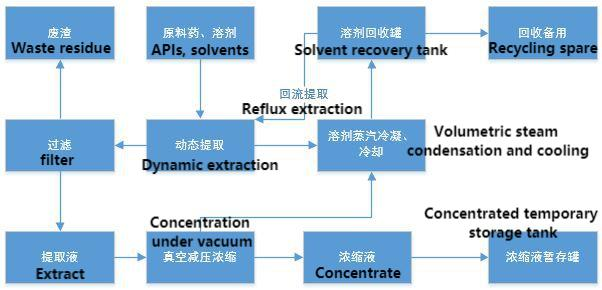

[Process flow]

Put the medicinal materials into the extraction tank,add 5-10 times the solvent such as water,ethanol,methanol,acetone,etc. (according to the process requirements). Turn on the heating system of the extraction tank to heat the extraction liquid to boiling for 20-30 minutes,and then use a suction filter tube to pump one third of the extraction liquid into the concentration tank. Close the extraction tank direct system and jacketed hot water,open the concentration tank direct system and heating system to keep the concentrated juice temperature at about 80℃,and the vacuum degree to keep at -0.05 to -0.08MPA. The secondary steam generated during concentration passes through the condenser. The cooler becomes the condensate and flows back to the extraction tank as a new solvent. Add the new solvent to the medicine. The new solvent passes through the medicinal material layer to the bottom of the extraction tank from top to bottom. The soluble components in the medicinal material are dissolved in the solvent in the extraction tank. It is pumped into the concentration tank,and the secondary steam generated by the concentration is sent to the extraction tank as a new solvent,forming a new solvent for reflux extraction,until it is completely dissolved (the extract is colorless) and the concentration continues until it is concentrated into the required specific gravity ointment,inside the extraction tank The colorless liquid can be reused next time. If it is extracted by organic solvent,add an appropriate amount of water first,open the system and jacket hot water,recover the solvent,and drain the slag.