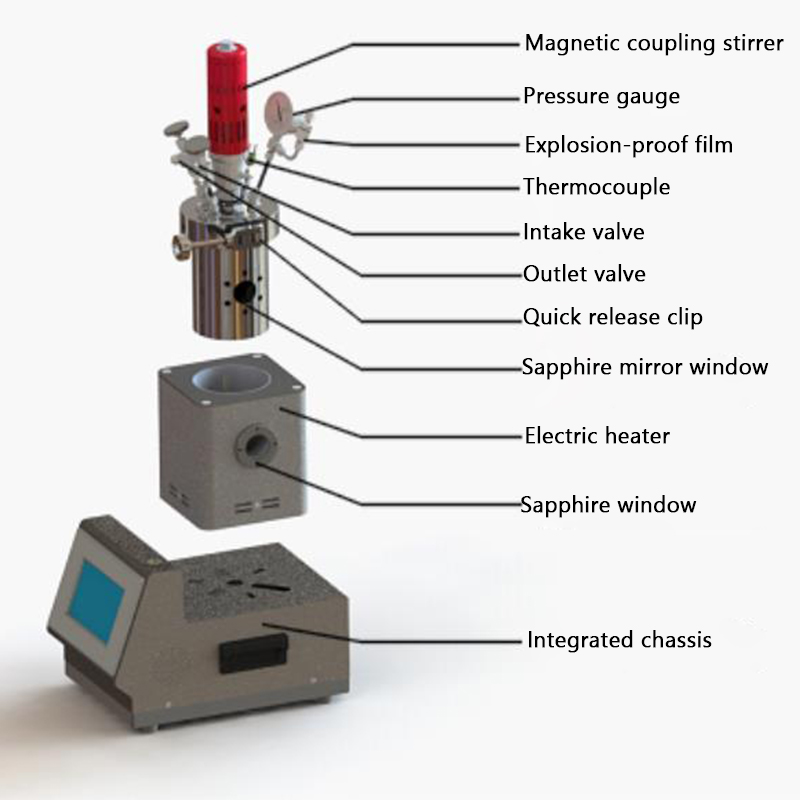

The window sapphire reaction kettle is pressure resistant and the medium is visible. It is used for visible reaction research, sampling analysis, multiphase behavior observation, spray observation of supercritical particle preparation, thermodynamic property research, long-time dissolution process observation, etc. It is used in various catalytic reactions, high-temperature and high-pressure synthesis, hydrogenation reaction, gas-liquid two-phase, liquid-liquid two-phase, exothermic reaction, composition test, stability, corrosion test, fine chemical industry, supercritical reaction, catalyst evaluation and development, etc. it is mainly distributed in petrochemical, chemical, pharmaceutical, polymer synthesis, metallurgy and other fields.

Item no.:

OLT-PR-100CSCCapacity:

100-1000mlVoltage:

220V 50HzCertificate:

CE CertificateWarranty:

1 yearThe window sapphire reaction kettle is pressure resistant and the medium is visible. It is used for visible reaction research, sampling analysis, multiphase behavior observation, spray observation of supercritical particle preparation, thermodynamic property research, long-time dissolution process observation, etc. It is used in various catalytic reactions, high-temperature and high-pressure synthesis, hydrogenation reaction, gas-liquid two-phase, liquid-liquid two-phase, exothermic reaction, composition test, stability, corrosion test, fine chemical industry, supercritical reaction, catalyst evaluation and development, etc. it is mainly distributed in petrochemical, chemical, pharmaceutical, polymer synthesis, metallurgy and other fields.

Speicifcation

| Model | OLT-PR(100\250\500)CSC |

| Capacity | 100ml\250ml\500ml |

| Material | Standard 316L can be customized (304, C276, B-2, zirconium, inconel-600) |

| Structural style | One button quick opening clip design |

| Usage temperature | RT-200℃, Customize |

| Heating method | Electric heating (integrated casting forming electric heating furnace) |

| Usage pressure | Up to 10MPa, customizable |

| Sealing form | O-ring self sealing |

| Stirring form | Mechanical stirring, speed: up to 1500rpm |

| Kettle cover interface | Temperature measuring port, pressure gauge port, proportional unloading valve port, air inlet and exhaust port |

| Control mode | Self developed control module is easy to operate and PID self-tuning temperature control is accurate |

| Extended function (optional) |

1. Isobaric feeding function: feed liquid phase materials in the reaction process (control the total amount) 2. High pressure feed pump: feed liquid phase materials in the reaction process (accurately control the flow rate) 3. Gas mass flowmeter: accurate measurement of gas cumulative flow and instantaneous flow 4. Built in cooling coil: can realize rapid cooling in the kettle 5. Process sampling function: rapid sampling and analysis in the reaction process 6. Condenser: realize condensation reflux or recovery function |

|

Pressure gauge: German WIKA shock-proof pressure gauge, high precision; 316L stainless steel material, anti-corrosion and durable. Optional diaphragm pressure gauge |

|

Explosion-proof components: The safety defense line, and the overpressure is automatically relieved. Hastelloy explosion-proof disc, corrosion-resistant, long service life |

|

Condensing tower: fin structure is adopted to greatly increase the heat dissipation area. Good protection of pressure gauge and proportional unloading valve |

|

Temperature measuring components: K-type thermocouple imported from OMEGA in the United States, with high precision and sensitive response. Quick plug connector, easy to disassemble. |

|

Valve: High temperature and high pressure right angle needle valve, standard 1 / 4 ", 316L stainless steel. Domestic high-end valves are standard, and imported valves can be selected as required. |

|

Magnetic coupling stirrer: magnetic coupling drive to solve the problem of stirring and sealing of high-pressure reaction kettle |

|

Paddle: standard three blade propelling paddle, the paddle type can be selected according to customer requirements |

|

Kettle body: The whole bar is processed by the CNC machining center once, without any welding points. The semi open ring quick opening design is adopted, which is more convenient for disassembly. The standard material is 316L. According to the anti-corrosion situation, Hastelloy, Monel, zirconium, titanium and other materials can be selected |

|

Control box & heating furnace: the control box and heating furnace are integrated to save space; The upper part is integrally cast into an electric heating furnace, which is durable; The lower control box can display and adjust the rotation speed, temperature in the kettle, furnace temperature, reaction kettle time, etc. Set the upper limit of furnace temperature, over temperature automatic power-off protection |

Standard configuration list

| No. | Name | QTY | Unit | Remark |

| 1 | Kettle body | 1 | Set | SS316L material |

| 2 | Machine case | 1 | Set | One-piece structure |

| 3 | Pressure gauge 0-16Mpa | 1 | Unit | Germany WIKA |

| 4 | Explosion-proof components | 1 | Piece | C276 explosion-proof film |

| 5 | Temperature measurement components | 1 | Stick | American OMEGA |

| 6 | Intake valve | 1 | Unit | SS316L material |

| 7 | Outlet valve | 1 | Unit | SS316L material |

| 8 | Thermowell | 1 | Stick | SS316L material |

| 9 | Bottom tube | 1 | Stick | SS316L material |

| 10 | Sealing ring | 1 | Unit | Imported perfluoroether |

| 11 | Magnetic coupling stirrer | 1 | Unit | SS316L material |

| 12 | Sapphire mirror |

2 | Piece |

Min diameter 20mm |

| 13 | Wrench |

1 | Unit |

Special removal tool |

Tags :