YK series magnetic stirring reaction kettle adopts desktop design, with compact and lightweight structure and exquisite appearance. Widely used in petroleum, chemical, pharmaceutical, material, metallurgy and other fields. Specifically, such as catalytic reaction, polymerization reaction, supercritical reaction, high temperature and high pressure synthesis, hydrogenation reaction, etc. It is the right-hand man of universities, research institutes and enterprise laboratories. The YK series is more convenient to use than the F and K series reactors. With one-button quick-open design, the reactor can be disassembled and assembled without any tools and screws.

Item no.:

OLT-PR-50YKCPayment:

100% prepayProduct origin:

Xiamen, ChinaCapacity:

50-2000mlVoltage:

108-240VCertificate:

CE certificateWarranty:

1 year|

Model

|

OLT-PR-50YKC

|

OLT-PR-100YKC

|

OLT-PR-150YKC

|

OLT-PR-200YKC

|

OLT-PR-250YKC

|

|

Volume(ml)

|

50

|

100

|

150

|

200

|

250

|

|

Service temperature(℃)

|

RT-300℃, Higher temperatures can be customized according to customer requirements

|

||||

|

Use pressure(Mpa)

|

Standard 10Mpa, customized according to customer requirements

|

||||

|

Heating power(w)

|

600

|

1000

|

1000

|

1500

|

1500

|

|

Control mode

|

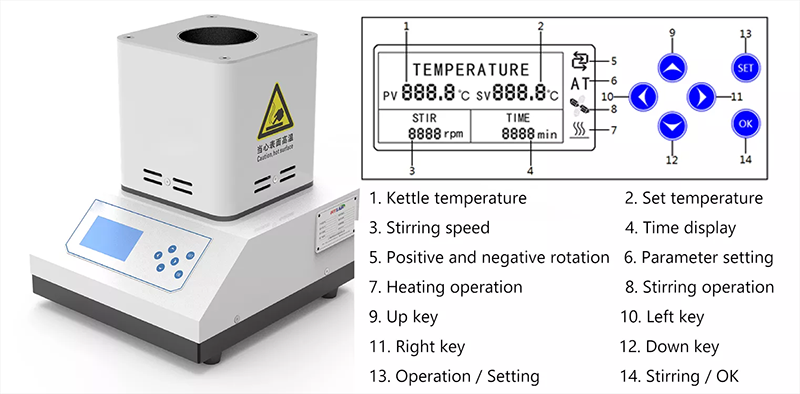

PID artificial intelligence adjustment, LCD digital display

|

||||

|

Mixing form

|

Magnetic stirring

|

||||

|

Mixing power(w)

|

80

|

||||

|

Stirring speed(rpm)

|

0-1500

|

||||

|

Sealing form

|

Upper and lower flange gasket seals

|

||||

|

Kettle lid interface

|

Temperature measuring port, pressure gauge port, proportional unloading valve port, air inlet, exhaust port

|

||||

|

Safety protection

|

Set upper temperature limit, over temperature alarm, self power-off protection

|

||||

|

Timing function

|

Working time and holding time can be set regularly

|

||||

|

Supply voltage

|

AC 108V-240V 50Hz

|

||||

|

Extended function (optional)

|

1. Isobaric feeding function: liquid phase material (total control) during the reaction

2. High-pressure feed pump: feed liquid-phase material during the reaction (accurately control the flow rate)

3. Gas mass flowmeter: Accurately measure gas cumulative flow, instantaneous flow

4. Built-in cooling coil: can achieve rapid cooling in the kettle

5. Process sampling function: rapid sampling analysis during the reaction process

6. Condenser: realize condensation reflux or recovery function

|

||||

|

Pressure gauge: German WIKA shock-proof pressure gauge, high precision; 316L stainless steel material, anti-corrosion and durable. Optional diaphragm pressure gauge |

|

Explosion-proof components: safety line of reaction kettle, automatic pressure relief for overpressure. American brand, safe and durable |

|

Condensing tower: The fin structure is adopted, which greatly increases the heat dissipation area. Good protection of pressure gauge and proportional unloading valve |

|

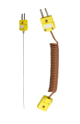

Temperature measuring components: K-type thermocouple imported from OMEGA in the United States, with high precision and sensitive response. Quick plug connector, easy to disassemble. |

|

Valve: high temperature and high pressure right angle needle valve, standard 1/4", 316L stainless steel material. Standard domestic high-end valve, imported valve can be selected according to requirements. |

|

Kettle body: The whole bar is processed by the CNC machining center once, without any welding points. The one button quick opening design is adopted to facilitate disassembly. The standard material is 316L. According to the anti-corrosion situation, Hastelloy, Monel, zirconium, titanium and other materials can be selected |

|

Control box & heating furnace: The heating furnace of the control box is integrated to save space; the upper part is integrally poured into the electric heating furnace, which is durable; the lower control box can display the adjustment speed, the temperature in the kettle, the furnace temperature, and the time of the reaction kettle. Set the upper limit of furnace temperature and over-temperature self-power-off protection |

| No. | Name | QTY | Unit | Remark |

| 1 | Kettle body | 1 | Set | SS316L material |

| 2 | Control Box & Heating Furnace | 1 | Set | One-piece structure |

| 3 | Pressure gauge 0-16Mpa | 1 | Unit | Germany WIKA |

| 4 | Explosion-proof components | 1 | Piece | C276 explosion-proof film |

| 5 | Temperature measurement components | 1 | Stick | American OMEGA |

| 6 | Intake valve | 1 | Unit | SS316L material |

| 7 | Outlet valve | 1 | Unit | SS316L material |

| 8 | Thermowell | 1 | Stick | SS316L material |

| 9 | Bottom tube | 1 | Stick | SS316L material |

| 10 | Sealing ring | 1 | Unit | Imported perfluoroether |

| 11 | Magnetic stirrer | 2 | Unit | High temperature magnon |

Tags :