In the chemical, pharmaceutical, new materials, food and other industries, the reactor is the core production equipment, and its performance directly affects product quality and production efficiency. In order to meet the needs of enterprises for precise temperature control, efficient stirring, safety and stability, OLLITAL brand high-performance reactors are strongly launched, with intelligent control, corrosion-resistant materials, and high-efficiency design to provide the industry with more reliable production solutions!

Precise temperature control to ensure stable reaction

OLLITAL reactors are equipped with intelligent temperature control systems, support PID precise adjustment, and can control the temperature difference within **±1°C. Whether it is high-temperature polymerization, low-temperature crystallization, or constant temperature catalysis**, the equipment can provide the best temperature control environment to ensure the stability and consistency of chemical reactions. At the same time, it supports a variety of temperature control methods such as electric heating, steam heating, and jacket cooling to meet different process requirements.

Learn more:

Intelligent temperature control reactor A series - suitable for laboratories and pilot production, providing a high-precision reaction environment.

Efficient stirring to improve production capacity and quality

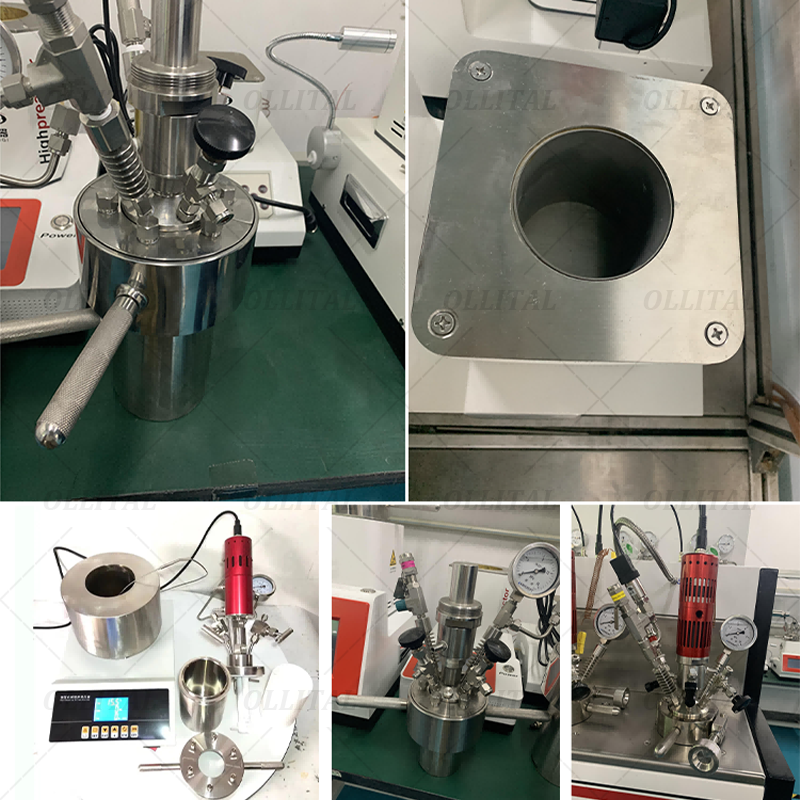

To optimize reaction efficiency, OLLITAL brand reactors are equipped with a variety of stirring systems (anchor type, paddle type, magnetic stirring, etc.), which can customize the speed, shear force, and mixing method according to the characteristics of the material, effectively preventing local overheating, sedimentation, agglomeration and other problems, ensuring that the material is uniform and fully reacted, and greatly improving product quality and production efficiency.

Learn more:

Efficient stirring reactor B series - suitable for complex processes such as high-viscosity materials and polymerization reactions.

Corrosion-resistant materials, safe and stable operation

OLLITAL brand reactors are made of highly corrosion-resistant materials such as stainless steel, titanium alloy, glass lining, Hastelloy, etc., which can withstand extreme working conditions such as strong acid, strong alkali, high pressure, and high temperature, extend the service life of the equipment, and reduce maintenance costs. In addition, the equipment is equipped with safety systems such as automatic pressure relief, gas protection, and real-time monitoring to ensure safe and stable operation under high pressure and high temperature environments.

Learn more:

Corrosion-resistant reactor C series - suitable for strong corrosion and high pressure reaction processes to ensure production safety.

Adaptable to multiple industries to meet personalized customization needs

OLLITAL brand reactors are widely used in fine chemicals, pharmaceutical synthesis, new material research and development, food processing, catalytic reactions and other industries, and support personalized customization of volume, material, stirring method, and temperature control system to ensure that the equipment and process requirements are perfectly matched, helping enterprises to improve production efficiency and achieve high-quality development.

Contact us to get customized reactor solutions

OLLITAL brand has always been committed to providing customers with efficient, accurate and safe reaction equipment. The latest smart reactor is now on the market. Welcome to consult. We will recommend the most suitable equipment according to your process needs and jointly promote industrial upgrading!

Contact information:

Tel: +86 159 6082 1529

Email: Kevin@ollital.com

Official website: www.ollital.com