[Background]

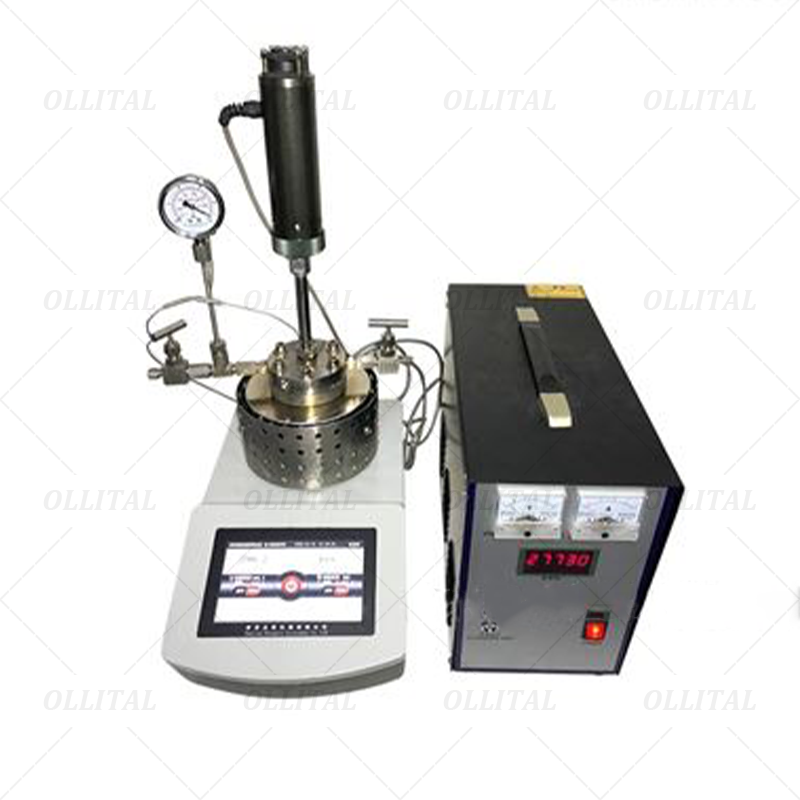

With the continuous development of chemical, pharmaceutical and material science fields, reactor technology is also constantly innovating. Although traditional stirred reactors perform well in many processes, in some special scenarios, the stirring device may cause a series of problems, such as poor sealing and increased risk of contamination. The emergence of unstirred reactors provides a new solution to these challenges and has become an innovative equipment that has attracted much attention in modern industry.

[Advantages of unstirred technology]

The reason why unstirred reactors are so popular is that they avoid many potential problems caused by mechanical stirring. First, the unstirred reactor eliminates the agitator, which completely solves the sealing problem caused by wear of traditional agitators, thereby greatly reducing the risk of external contaminants entering the reactor during the reaction. This is especially important for high-purity chemical reactions and biopharmaceutical processes, ensuring high cleanliness and efficiency of the production process.

Secondly, under high temperature, high pressure or ultra-low temperature conditions, unstirred reactors show significant advantages. Since there are no mechanical parts, there is no need to worry about the failure of the agitator under extreme conditions, thereby improving the safety and reliability of the equipment. Especially in some extreme environments such as ultra-high pressure synthesis and hydrogenation reactions, the non-stirring reactor can effectively avoid possible failures of traditional equipment.

[Expansion of application fields]

With the maturity of non-stirring reactor technology, its application scope is also expanding. At present, non-stirring reactors have been widely used in high-end pharmaceuticals, fine chemicals, new materials development and other fields. Especially in some demanding reaction processes, such as catalytic reactions and crystal growth, non-stirring reactors have become the core equipment in these process flows due to their non-contact and pollution-free characteristics.

In addition, with the increasingly stringent environmental protection regulations, chemical companies are also constantly improving their environmental protection requirements for reactors. Due to its simple structure, easy cleaning and maintenance, the non-stirring reactor has shown significant advantages in reducing solvent residues and reducing wastewater treatment pressure. Therefore, it is increasingly favored in production scenarios with strict environmental protection requirements.

[Future Outlook]

The rise of non-stirring reactors marks an important innovation in the field of chemical equipment. Although this technology is still in the promotion stage, its application prospects in high-precision and extreme condition reactions are very broad. With the continuous advancement of technology, non-stirring reactors are expected to replace some traditional reaction equipment in the future and become the mainstream choice in the chemical industry.

[Conclusion]

Non-stirring reactors bring new possibilities to chemical production. It not only solves many pain points in traditional stirred reactors, but also shows unique advantages in the production process with high cleanliness and high safety requirements. With the introduction of more innovative technologies, non-stirring reactors will occupy a more important position in future industrial production.