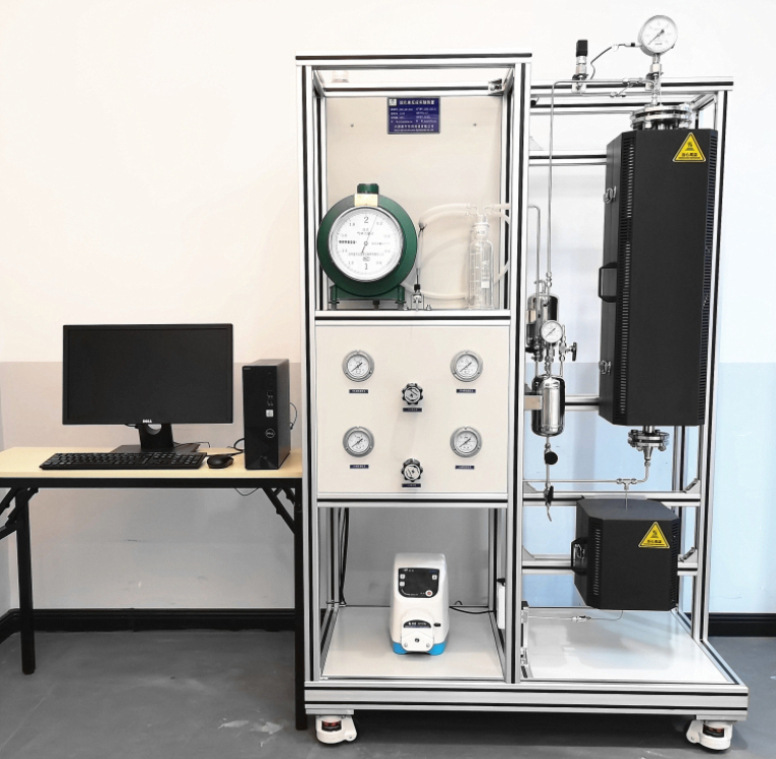

Pro-Hydrogen Ammonization Reaction Unit

Item no.:

XYHC-GDC-288Payment:

T/TProduct origin:

ChinaLead Time:

15-25 daysThis device can be used for atmospheric pressure, high pressure, high temperature continuous reaction test, suitable for universities, research institutes for catalyst performance evaluation and screening and other research work.

Application Fields

-Can be widely used in petrochemical, chemical chemistry, scientific research and teaching fields.

-The operating conditions of the device are very wide, with strong generality;

-It can be used for the determination of some common parameters in catalyst research and improvement: reaction temperature, reaction pressure and feed flow rate.

-It can be used to test the role of catalysts in hydrogenation reactions.

-It can be used for roughing, selecting and activity testing of catalysts.

-Tests the catalyst's validity.

Function

The device is a vertical frame structure, designed with a liquid vaporization furnace, a reaction heating furnace, the reactor is a fixed bed, and the reactor is a three-stage temperature control. The gas raw material enters into the reactor after depressurization through mass flow meter to control the flow rate, and the liquid raw material enters into the vaporization furnace after metering by metering pump to vaporize and then enters into the reactor to carry out the reaction. The reaction product is analyzed online and the rest of the gas is vented. The device can be used for the study of reaction mechanism and reaction kinetics, exploration of reaction conditions, catalyst screening, evaluation and so on.

Technical parameters

Reaction pressure: 0.1~20.0MPa

Control accuracy ±1% F. S.

Reaction temperature: room temperature~1000℃

Control accuracy ±1℃

Gas flow rate: 20~2000ml/min

Control accuracy ±1% F. S.

Catalyst loading capacity: 2ml~50ml

Functional features

-The shape of the device can be designed as open frame and desktop type according to the requirements;

-Combination of computer automation and manual dual-mode control can be realized for easy operation;

-Instruments, pumps and valve parts are made of domestic and foreign famous brand products to ensure the reliability and stability of the system;

-Reaction condition high and low limit interlock alarm is set up to ensure the safe operation of the device;

-Each component adopts modularized design with strong versatility, which is convenient for installation and maintenance;

-System flow, catalyst loading, feed rate, media type, operating pressure, etc. can be specially designed according to user requirements.

Equipment Pictures

Tags :