Tube Sterilizer is a high-efficiency sterilization equipment widely used in biopharmaceutical, food industry and laboratory research fields. It is designed to completely and reliably eliminate microorganisms and harmful organisms, ensuring the quality and safety of the final product.

Item no.:

OLT-168Product origin:

ChinaLead Time:

7-10 daysTube Sterilizer is a high-efficiency sterilization equipment widely used in biopharmaceutical, food industry and laboratory research fields. It is designed to completely and reliably eliminate microorganisms and harmful organisms, ensuring the quality and safety of the final product.

Key features of tube sterilizers include:

- Efficient sterilization: Tube sterilizers use hot air or steam to achieve an efficient sterilization process. High temperature sterilization can completely inactivate bacteria, viruses and other microorganisms, ensuring product sterility.

- Multipurpose: These devices are suitable for a variety of containers and pipes, including glass bottles, plastic bottles, infusion bags, piping systems, etc., providing a wide range of applications.

- Automated controls: Modern tube sterilizers often feature advanced automated control systems that allow easy setting of temperature, pressure and processing time, ensuring accuracy and repeatability of the sterilization process.

- Security: Security is one of the primary considerations. These devices often feature multiple safety mechanisms, including emergency stop buttons, overheating protection and pressure monitoring, to ensure the safety of operators and equipment.

- Customizability: According to user needs, tube sterilizers of different sizes and capacities can be customized to accommodate different scales of production and research.

In short, the tube sterilizer is an indispensable piece of equipment used to ensure the sterility and quality of products and is widely used in fields such as medicine, food, chemical industry, and laboratories. Its efficiency, reliability and safety make it a critical tool in a variety of industrial and research environments.

Product Display:

Machine features:

1. Except for motors, electrical appliances and soft connections, they are made of high- quality stainless steel 304 or 316L.

2. It is equipped with CIP / SIP system. The pipeline is sterilized before production and then sterilized at 125 ℃.

3. The product is a control system composed of man-machine interface and PLC, which is easy to operate.

4. All joints and connection points of sterilizer pipeline are provided with aseptic protection to strictly ensure product quality.

5. With its own heat recovery system, it can save more than 30% energy compared with the same type of equipment in the industry.

About Us:

Ollital Technology in 2003, having over 150 employees (till August, 2022), Ollital Technology It is a high-tech enterprise focused on research and development, specializing in the production of industrial cleaning machinery, dry ice particle machinery, dry ice cleaning machinery,plasma cleaning machinery, laser cleaning machinery, ultrasonic equipment and other fields of products.

Ollital gathering up a professional team of experts, scholars as well as other scientific research personnels, our company has obtained patents and expanded marketing for multiple products such as the self-developed Biochemistry analyzer, Ultrasonic Equipment, Lab Reactor, Medical Microbiological Detection equipment, Life Science Instrument.

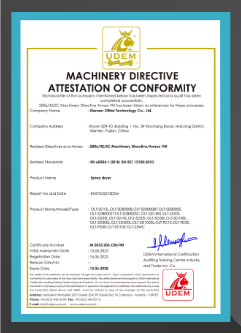

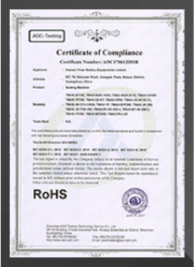

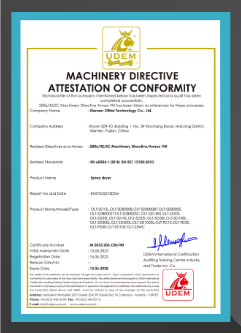

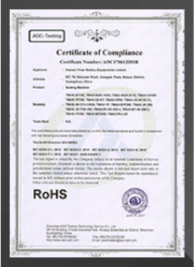

Ollital Technology has certificates including ISO9001, ISO 14001, CE, NSF, EN, FDA.

Ollital Technology has own high reputation in more than 70 countries and regions, provide technical support for tens of thousands organizations to solve problems within their research, special for university, research institutes, industries, inspection agencies, etc. We now have long-term business partners in more than 130 countries.