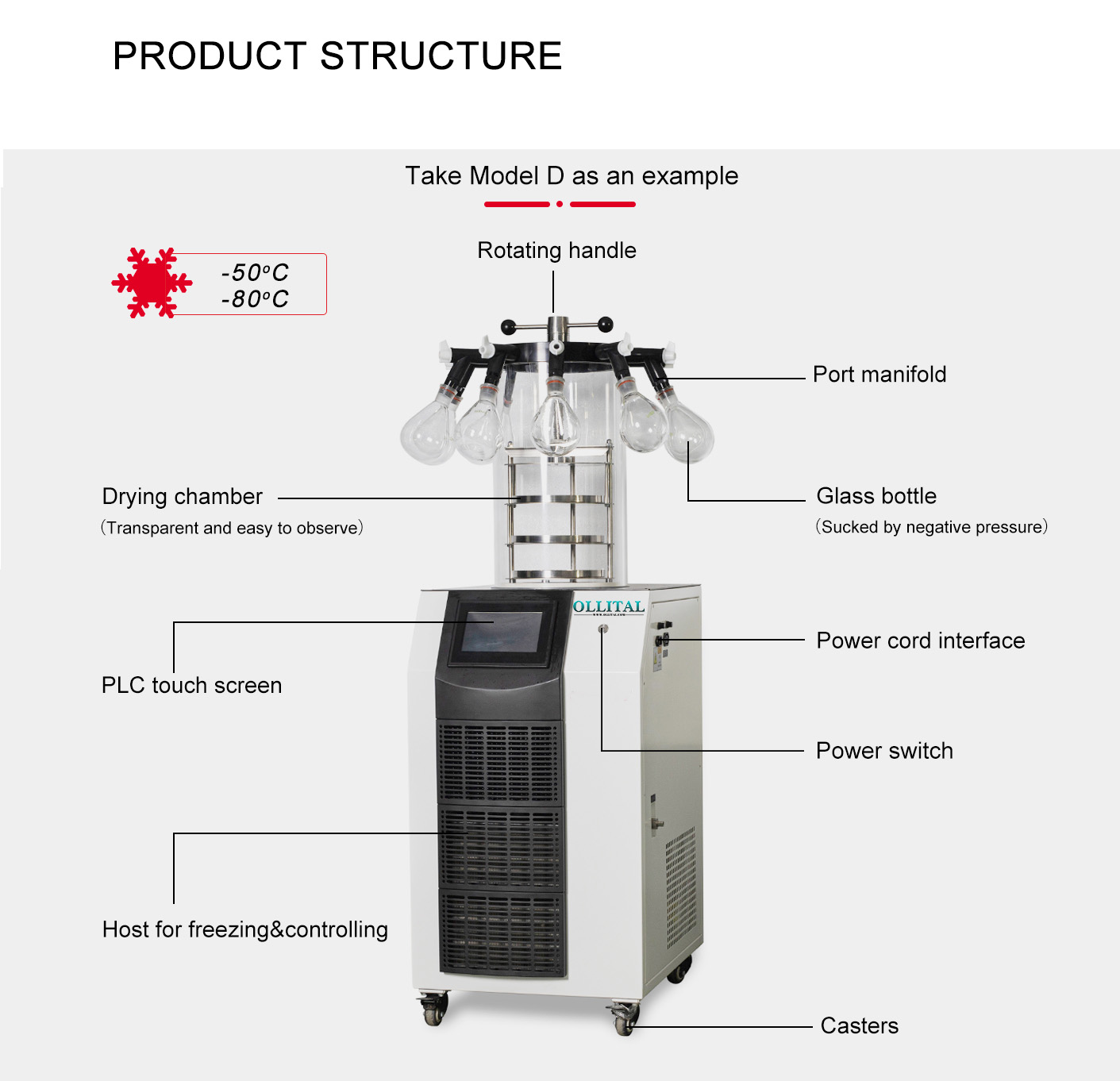

Freeze Dryer is a state-of-the-art solution for preserving perishable materials and delicate substances through the process of freeze-drying, also known as lyophilization. This advanced technology ensures the retention of flavor, nutritional value, and overall quality while extending the shelf life of a wide range of products.

Item no.:

OLT-168Product origin:

ChinaLead Time:

7-10 daysFreeze Dryer is a state-of-the-art solution for preserving perishable materials and delicate substances through the process of freeze-drying, also known as lyophilization. This advanced technology ensures the retention of flavor, nutritional value, and overall quality while extending the shelf life of a wide range of products.

Key Features and Benefits:

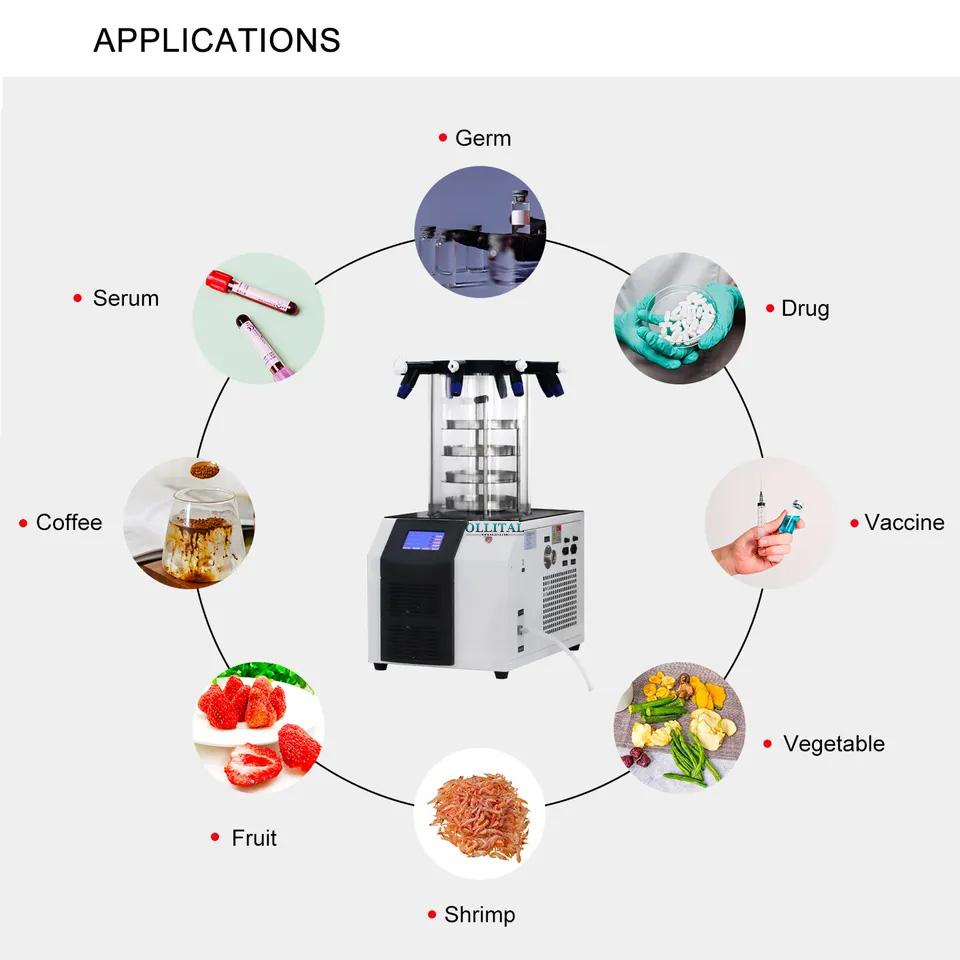

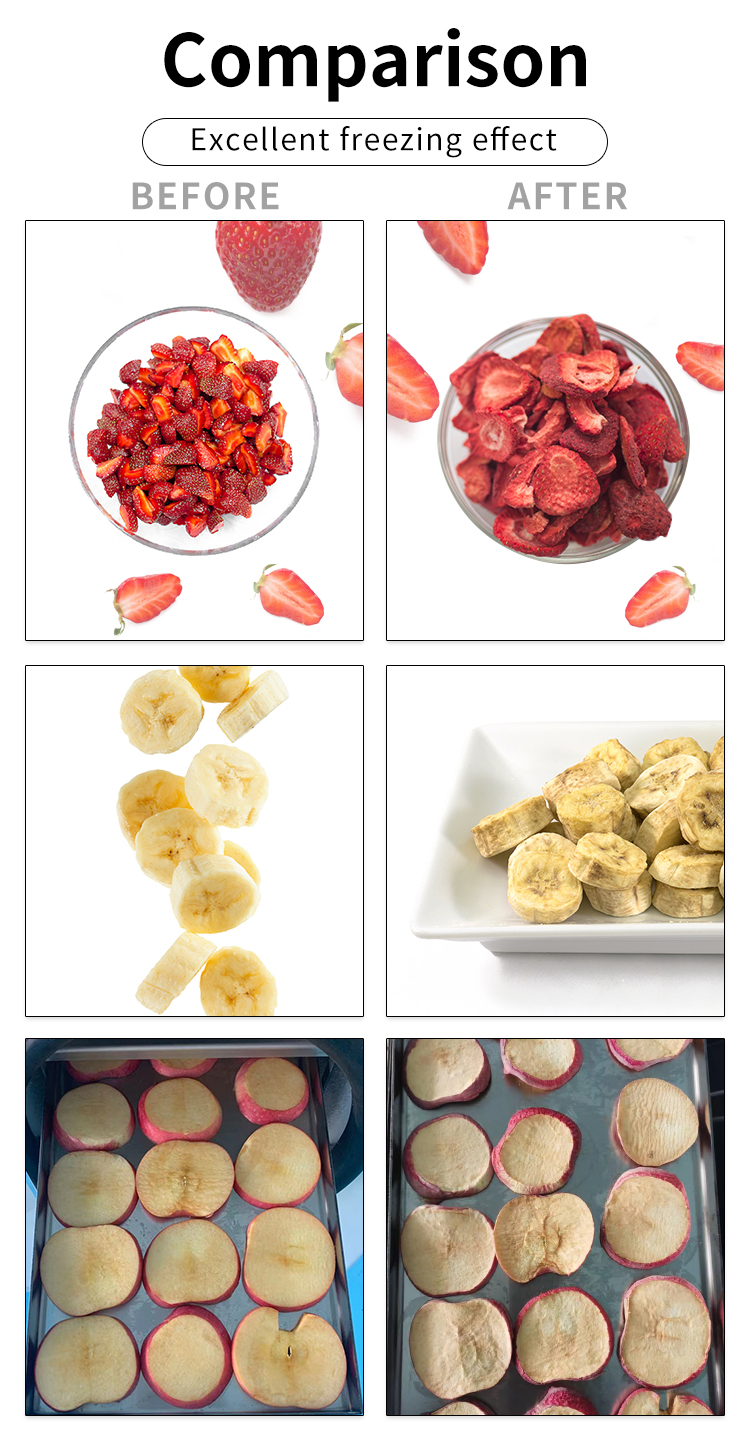

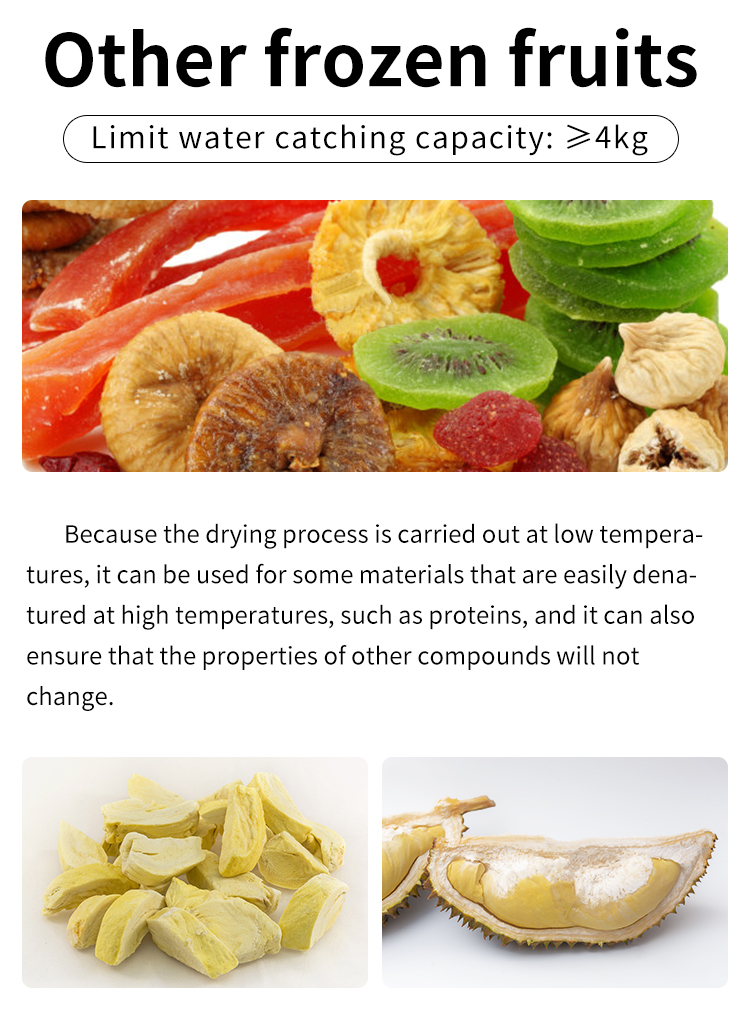

- Precise Preservation: Freeze drying removes moisture from products while maintaining their original structure, making it ideal for preserving fruits, vegetables, meats, and pharmaceuticals. It ensures minimal nutrient loss and flavor alteration.

- Versatile Applications: Our Freeze Dryer is suitable for both food and non-food applications. From creating instant coffee and soups to preserving vaccines and biological samples, its versatility knows no bounds.

- Gentle Drying Process: The low-temperature drying process avoids thermal degradation and oxidation, ensuring the product's integrity and quality.

- Long Shelf Life: Freeze-dried products have an extended shelf life, making them suitable for long-term storage and distribution.

- Customizable Drying Cycles: Tailor the drying process to your specific needs with programmable drying cycles. Adjust parameters such as temperature, vacuum levels, and drying times to achieve optimal results.

- User-Friendly Interface: The intuitive control system allows for easy monitoring and control of the drying process, ensuring consistency and reliability.

- Energy Efficiency: Our Freeze Dryer is designed with energy efficiency in mind, reducing operating costs while delivering exceptional results.

Our Freeze Dryer is a reliable and efficient solution for industries requiring top-quality preservation. Whether you're in the food, pharmaceutical, or biotechnology sector, this advanced technology ensures the longevity and quality of your products, making it an invaluable asset to your operations.

About Us

Ollital Technology in 2003, having over 150 employees (till August, 2022), Ollital Technology It is a high-tech enterprise focused on research and development, specializing in the production of industrial cleaning machinery, dry ice particle machinery, dry ice cleaning machinery,plasma cleaning machinery, laser cleaning machinery, ultrasonic equipment and other fields of products.

Ollital gathering up a professional team of experts, scholars as well as other scientific research personnels, our company has obtained patents and expanded marketing for multiple products such as the self-developed Biochemistry analyzer, Ultrasonic Equipment, Lab Reactor, Medical Microbiological Detection equipment, Life Science Instrument.

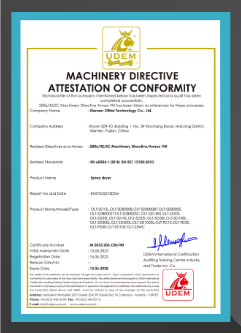

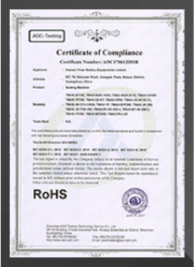

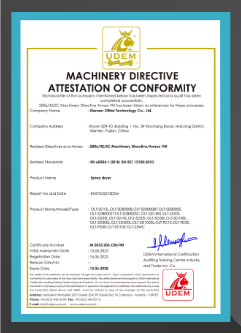

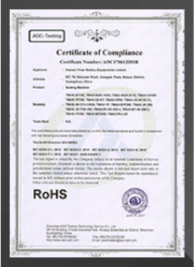

Ollital Technology has certificates including ISO9001, ISO 14001, CE, NSF, EN, FDA.

Ollital Technology has own high reputation in more than 70 countries and regions, provide technical support for tens of thousands organizations to solve problems within their research, special for university, research institutes, industries, inspection agencies, etc. We now have long-term business partners in more than 130 countries.