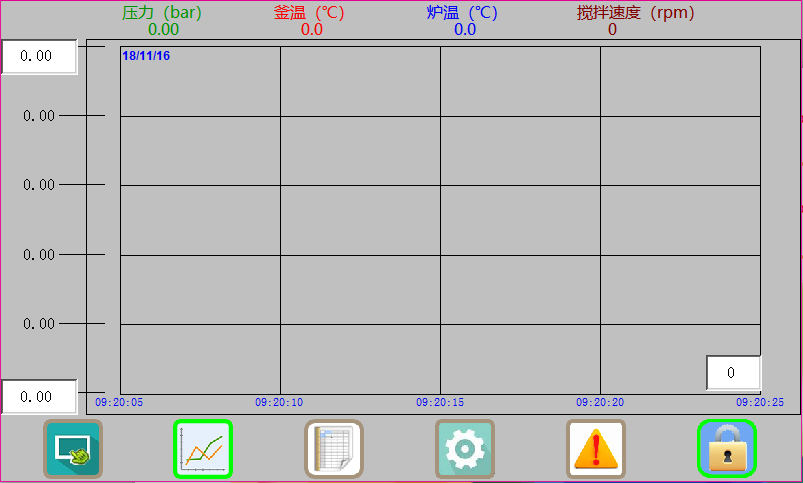

The touch screen reactor is controlled and operated on the basis of the standard model. The touch screen reactor can collect temperature, pressure, rotation speed and other data, store and export data curve analysis. Greatly improve the efficiency of the experiment and realize unattended operation.

Item no.:

OLT-PR-100CPCapacity:

100-2000mlVoltage:

220V 50HzCertificate:

CE CertificateWarranty:

1 yearThe touch screen reactor is controlled and operated on the basis of the standard model. The touch screen reactor can collect temperature, pressure, rotation speed and other data, store and export data curve analysis. Greatly improve the efficiency of the experiment and realize unattended operation.

| Touch screen flange magneton reactor |  |

| Touch screen flange mechanical reactor |  |

| Touch screen quick opening magneton reactor |  |

| Touch screen quick opening mechanical reaction kettle |  |

| Touch screen one button quick opening of Magnon reactor |  |

| Touch screen one key quick start mechanical reaction kettle |  |

Speicifcation

| Model | OLT-PR(100\250\500)CP |

| Capacity | 100ml\250ml\500ml |

| Material | Standard 316L can be customized (304, C276, B-2, zirconium, inconel-600) |

| Structural style | One button quick opening clip design/ quick opening design/ flange design |

| Usage temperature | RT-200℃, Customize |

| Heating method | Electric heating (integrated casting forming electric heating furnace) |

| Usage pressure | Up to 10MPa, customizable |

| Sealing form | O-ring self sealing |

| Stirring form | Mechanical stirring, Magnetic |

| Kettle cover interface | Temperature measuring port, pressure gauge port, proportional unloading valve port, air inlet and exhaust port |

| Control mode | Touch screen |

| Extended function (optional) |

1. Isobaric feeding function: feed liquid phase materials in the reaction process (control the total amount) 2. High pressure feed pump: feed liquid phase materials in the reaction process (accurately control the flow rate) 3. Gas mass flowmeter: accurate measurement of gas cumulative flow and instantaneous flow 4. Built in cooling coil: can realize rapid cooling in the kettle 5. Process sampling function: rapid sampling and analysis in the reaction process 6. Condenser: realize condensation reflux or recovery function |

Tags :