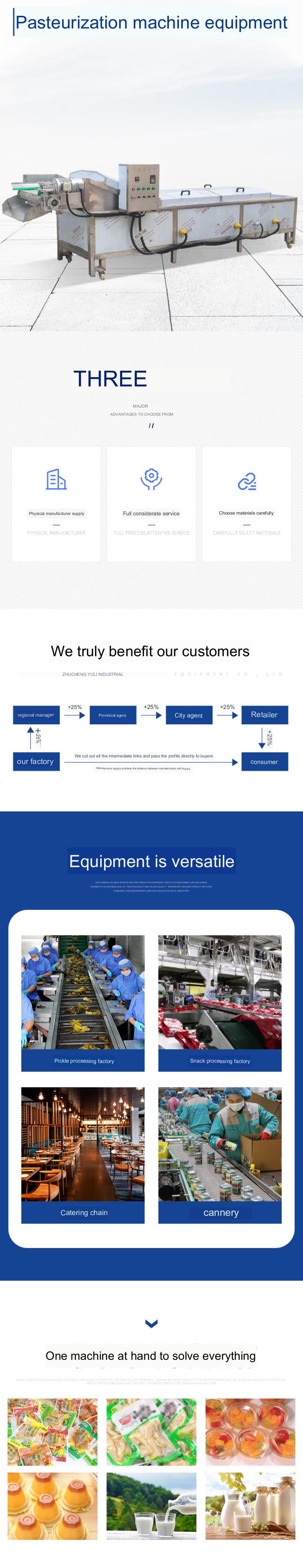

Pasteurization is a critical process in the food industry, aimed at enhancing food safety by reducing or eliminating harmful microorganisms present in various food products. This essential procedure involves heating the food to a specific temperature for a set duration to destroy pathogens while preserving the food's quality.

Item no.:

OLT-168Product origin:

ChinaLead Time:

7-10 days

Pasteurization is a critical process in the food industry, aimed at enhancing food safety by reducing or eliminating harmful microorganisms present in various food products. This essential procedure involves heating the food to a specific temperature for a set duration to destroy pathogens while preserving the food's quality. Here are the key functions and benefits of pasteurization:

- Pathogen Inactivation:Pasteurization effectively kills or inactivates harmful bacteria, viruses, yeasts, and molds present in food, most notably pathogens like Salmonella, E. coli, and Listeria.

- Shelf Life Extension:By eliminating or reducing spoilage microorganisms, pasteurization extends the shelf life of perishable foods, reducing food waste and enabling longer storage.

- Preservation of Nutrients:Unlike more aggressive sterilization methods, pasteurization is gentler and preserves the nutritional content, flavor, and texture of the food.

- Improved Safety:Pasteurization enhances food safety, making products like milk, fruit juices, and liquid eggs safer for consumption, especially for vulnerable populations such as children, the elderly, and individuals with weakened immune systems.

- Dairy Industry:In the dairy industry, pasteurization is widely used to eliminate harmful bacteria while maintaining the taste and quality of milk, cream, and dairy products.

- Juice and Beverage Industry:Fruit juices, soft drinks, and other beverages undergo pasteurization to ensure they are free from pathogens and can be stored at room temperature.

- Brewery and Winery:In brewing and winemaking, pasteurization is employed to stabilize the product, prevent refermentation, and improve product consistency.

- Food Manufacturing:Various food products, including sauces, soups, and liquid egg products, are pasteurized to ensure safety and extend their shelf life.

- Customization:Pasteurization processes can be tailored to suit specific products, allowing for variations in temperature and time to achieve the desired pathogen reduction.

- Regulatory Compliance:Pasteurization is often a regulatory requirement to ensure food safety and compliance with health standards.

Overall, pasteurization plays a crucial role in safeguarding public health by reducing the risk of foodborne illnesses. It is a fundamental practice in the food industry, allowing consumers to enjoy a wide range of safe and nutritious products.

About Us

Ollital Technology in 2003, having over 150 employees (till August, 2022), Ollital Technology It is a high-tech enterprise focused on research and development, specializing in the production of industrial cleaning machinery, dry ice particle machinery, dry ice cleaning machinery,plasma cleaning machinery, laser cleaning machinery, ultrasonic equipment and other fields of products.

Ollital gathering up a professional team of experts, scholars as well as other scientific research personnels, our company has obtained patents and expanded marketing for multiple products such as the self-developed Biochemistry analyzer, Ultrasonic Equipment, Lab Reactor, Medical Microbiological Detection equipment, Life Science Instrument.

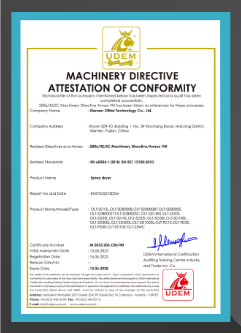

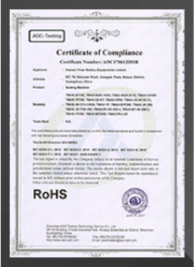

Ollital Technology has certificates including ISO9001, ISO 14001, CE, NSF, EN, FDA.

Ollital Technology has own high reputation in more than 70 countries and regions, provide technical support for tens of thousands organizations to solve problems within their research, special for university, research institutes, industries, inspection agencies, etc. We now have long-term business partners in more than 130 countries.

Tags :