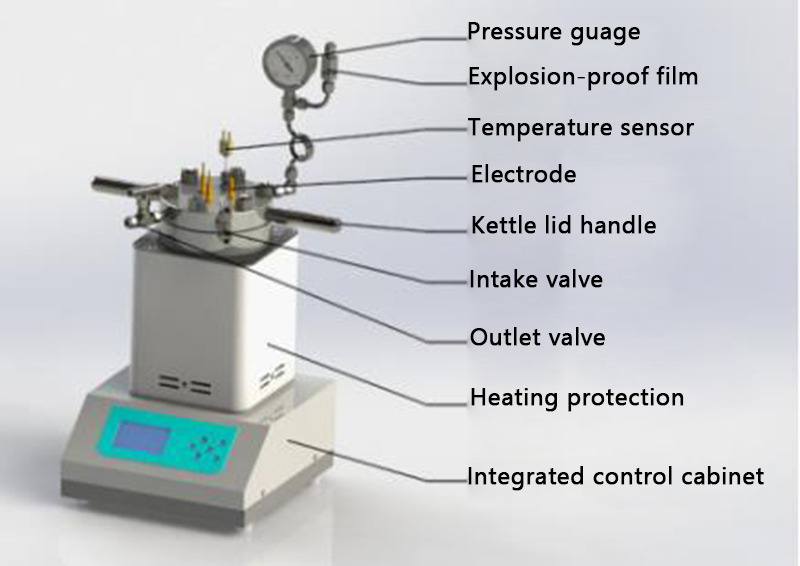

Based on the basic functions of the reaction kettle, the electrochemical reaction kettle superimposes the electrochemical functions to achieve the chemical reaction under controllable conditions such as temperature and pressure. The volume of the electrochemical reactor can be customized according to requirements. The maximum temperature is 300 ℃, and the maximum pressure is 10MPa. Special cases can be customized according to requirements.

Item no.:

OLT-PR-100DXPayment:

100% prepayProduct origin:

Xiamen, ChinaCapacity:

100-2000mlVoltage:

108-240VCertificate:

CE certificateWarranty:

1 year| Model | OLT-PR(50\100\250\500)DX |

| Capacity | 50ml\100ml\250ml\500ml customize |

| Material | Standard 316L can be customized (304, C276, B-2, zirconium, inconel-600) |

| Structural style | Fastening structure of upper and lower flange bolts and nuts |

| Usage temperature | RT-300℃, Customize |

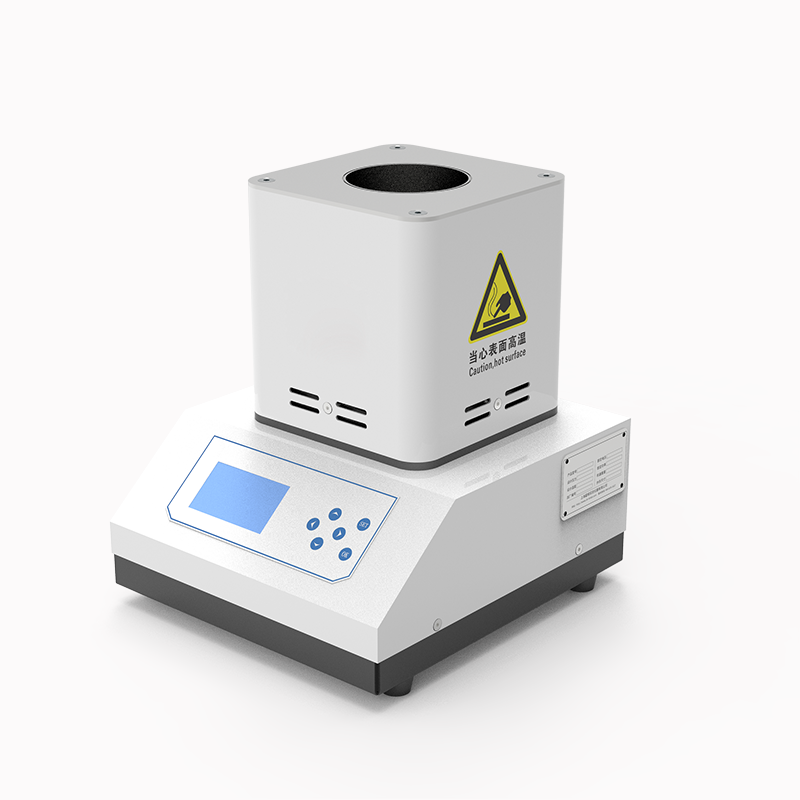

| Heating method | Electric heating (integrated casting forming electric heating furnace) |

| Usage pressure | Up to 5MPa, customizable |

| Sealing form | Upper and lower flange gasket seal |

| Kettle cover interface | Temperature measuring port, pressure gauge port, proportional unloading valve port, air inlet and exhaust port |

| Control mode | Self developed control module is easy to operate and PID self-tuning temperature control is accurate |

| Extended function (optional) |

1. Isobaric feeding function: feed liquid phase materials in the reaction process (control the total amount) 2. High pressure feed pump: feed liquid phase materials in the reaction process (accurately control the flow rate) 3. Gas mass flowmeter: accurate measurement of gas cumulative flow and instantaneous flow 4. Built in cooling coil: can realize rapid cooling in the kettle 5. Process sampling function: rapid sampling and analysis during reaction 6. Condenser: realize condensation reflux or recovery function |

|

Pressure gauge: German WIKA shock-proof pressure gauge, high precision; 316L stainless steel material, anti-corrosion and durable. Optional diaphragm pressure gauge |

|

Explosion-proof components: The safety defense line, and the overpressure is automatically relieved. Hastelloy explosion-proof disc, corrosion-resistant, long service life |

|

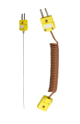

Temperature measuring components: K-type thermocouple imported from OMEGA in the United States, with high precision and sensitive response. Quick plug connector, easy to disassemble. |

|

Valve: High temperature and high pressure needle valve, standard 1 / 4 ", 316L stainless steel. Domestic high-end valves are standard, and imported valves can be selected as required. |

|

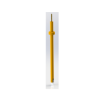

Electrode: electrode size can be customized |

|

The whole bar is processed by the CNC machining center once, without any welding points. The standard material is 316L. According to the anti-corrosion situation, Hastelloy, Monel, zirconium, titanium and other materials can be selected |

|

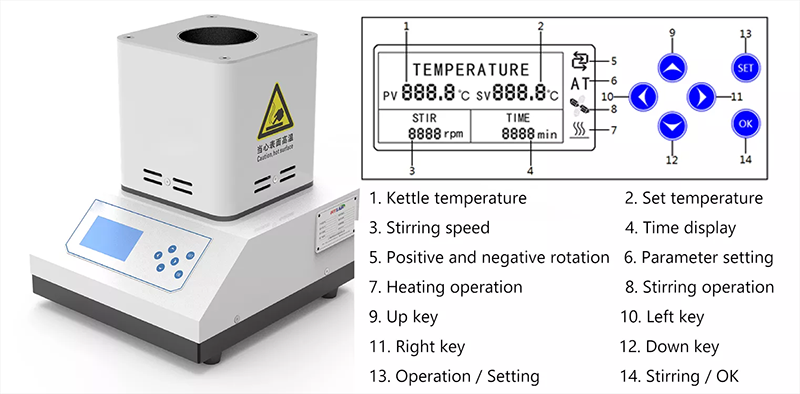

Control box & heating furnace: The heating furnace of the control box is integrated to save space; the upper part is integrally poured into the electric heating furnace, which is durable; the lower control box can display the adjustment speed, the temperature in the kettle, the furnace temperature, and the time of the reaction kettle. Set the upper limit of furnace temperature and over-temperature self-power-off protection |

| No. | Name | QTY | Unit | Remark |

| 1 | Kettle body | 1 | Set | SS316L material |

| 2 | Control Box & Heating Furnace | 1 | Set | One-piece structure |

| 3 | Electrode |

1 | Unit | Size can be customize |

| 4 | Pressure gauge 0-16Mpa | 1 | Unit | Germany WIKA |

| 5 | Explosion proof components |

1 | Piece | C276 explosion proof flm |

| 6 | Temperature measurement components | 1 | Stick | American OMEGA |

| 7 | Intake valve | 1 | Unit | SS316L material |

| 8 | Outlet valve | 1 | Unit | SS316L material |

| 9 | Thermowell | 1 | Stick | SS316L material |

| 10 | Bottom tube | 1 | Stick | SS316L material |

| 11 | Graphite metal gasket | 1 | Unit | |

| 12 | Wrench | 1 | Unit | Dedicated removal tool |

Tags :