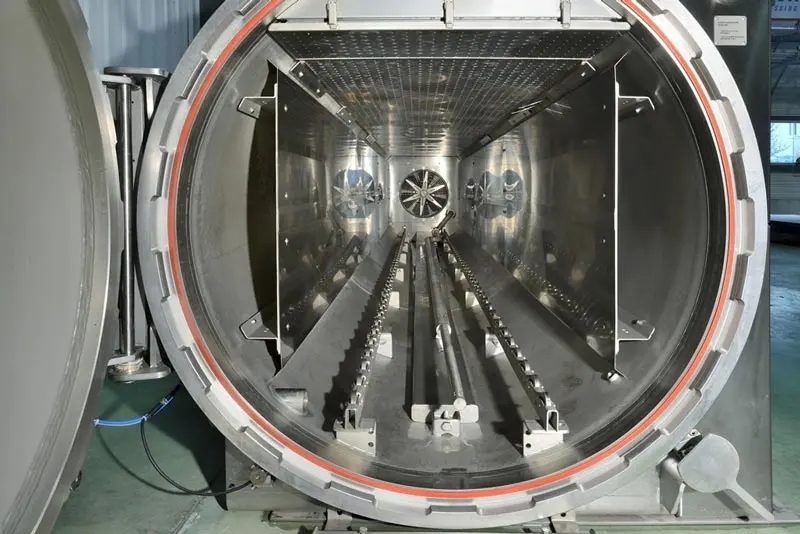

By adding a fan on the basis of steam sterilization, the heating medium and the packaged food are in direct contact and forced convection, and the presence of air in the sterilizer is allowed. The pressure can be controlled independently of the temperature. The sterilizer can set multiple stages according to different products of different packages.

Item no.:

OLT-168Product origin:

ChinaLead Time:

7-10 days

By adding a fan on the basis of steam sterilization, the heating medium and the packaged food are in direct contact and forced convection, and the presence of air in the sterilizer is allowed. The pressure can be controlled independently of the temperature. The sterilizer can set multiple stages according to different products of different packages.

- Precise sterilization: Steam sterilizers ensure precise and effective elimination of harmful microorganisms, including bacteria, viruses and spores.

- Versatility: They can sterilize a wide range of medical and laboratory equipment, instruments and materials, ensuring complete infection control.

- Rapid Sterilization: Steam sterilization shortens cycle times, minimizing equipment downtime and increasing operational efficiency.

- High temperature and high pressure: The combination of high temperature and high pressure ensures complete sterilization, even in hard-to-reach areas.

- Reliable and repeatable: Steam sterilization delivers consistent results that meet strict quality assurance standards.

- Environmentally Friendly: It utilizes water and electricity, making it an environmentally friendly option compared to some chemical sterilization methods.

- Minimal residue: Steam leaves no harmful residues or by-products, ensuring the safety of sterilized items.

- Cost-effective: Steam sterilizers are durable, require low maintenance and require reduced consumables, resulting in long-term cost savings.

- User-Friendly Controls: Modern steam sterilizers are equipped with intuitive control systems that are easy to operate and monitor.

- Safety features: include safety mechanisms that prevent accidents, ensure user well-being, and protect valuable equipment and materials.

About Us

Ollital Technology in 2003, having over 150 employees (till August, 2022), Ollital Technology It is a high-tech enterprise focused on research and development, specializing in the production of industrial cleaning machinery, dry ice particle machinery, dry ice cleaning machinery,plasma cleaning machinery, laser cleaning machinery, ultrasonic equipment and other fields of products.

Ollital gathering up a professional team of experts, scholars as well as other scientific research personnels, our company has obtained patents and expanded marketing for multiple products such as the self-developed Biochemistry analyzer, Ultrasonic Equipment, Lab Reactor, Medical Microbiological Detection equipment, Life Science Instrument.

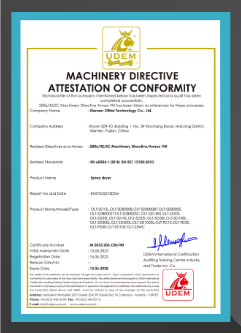

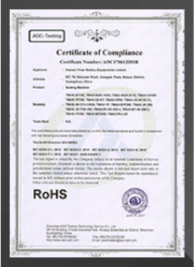

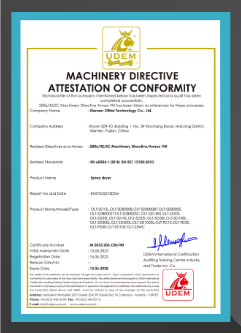

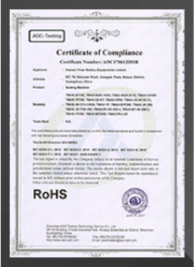

Ollital Technology has certificates including ISO9001, ISO 14001, CE, NSF, EN, FDA.

Ollital Technology has own high reputation in more than 70 countries and regions, provide technical support for tens of thousands organizations to solve problems within their research, special for university, research institutes, industries, inspection agencies, etc. We now have long-term business partners in more than 130 countries.