Black garlic conical fermenter tank

Item no.:

OLT-10/15/20/30/50/1Payment:

T/TProduct origin:

China

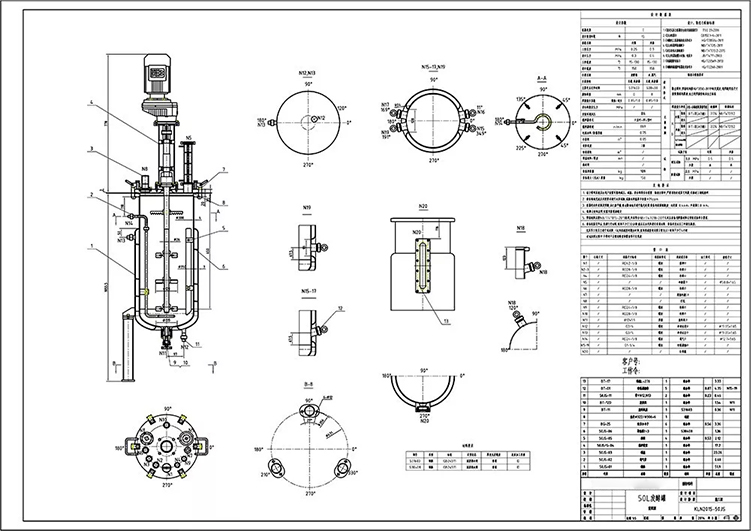

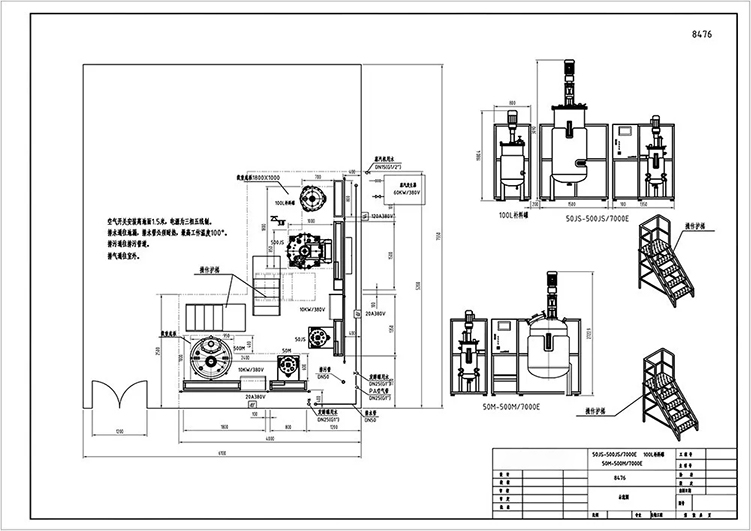

Production Standard Automatic Bioreactor Fermentor

Product Description

Technical Data

|

TYPE

|

OLT-5/7/10BGZOLT

|

-5/7/10JGZ

|

|

Total Volume

|

5/7/10L

|

|

|

Vessel

|

316L Stainless Steel +Borosilicate Glass

|

|

|

Stirrer

|

Top driven

|

Bottom Driven by magnetic Coupling

|

|

Sterilization

|

In situ Sterilization (Steam Source External)

|

|

|

Basic Features

|

Temperature,RPM,PH,DO,Antifoam,Feed,Aeration,Pressure

|

|

|

Advanced Features

|

Level,Weight Feed,Multi-Feeds, Mehanol&Ethanol,Exhaust O2&CO2

|

|

|

Controller

|

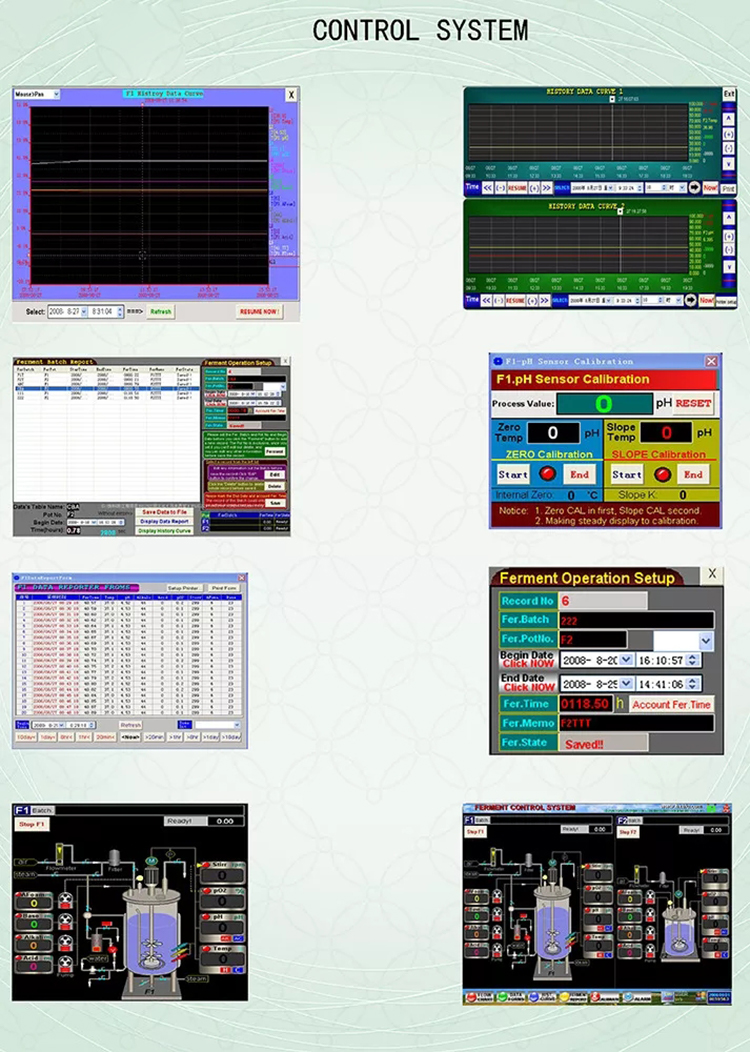

OLT-7000 Technical parameter

|

|

|

|

Parameter

|

Guideline

|

Controller data processing function

|

|

|

pH

|

Displaying range: 0.00~14.00±0.01

Auto-control range:2.00~12.00±0.05 Fermentation process control (According to the fermentation time, auto- control pH fluent, at least10 parts) |

pH value historical and trend curve analysis Acid, alkali dosage curve analysis

Batch report form analysis Acid, alkali total dosage record Keep |

|

|

Antifoam

|

Automatic PID control and alarm

Fermentation process control (According to the fermentation time, auto- control antifoam fluent, at least10 parts) |

Antifoam value historical and trend curve analysis Foam error state record

antifoam total dosage record Batch report form analysis Keep |

|

|

Rpm

|

Automatic enactment and control(50~1000rpm±5‰)

Fermentation process control (According to the fermentation time, auto-control rev fluent, at least10 parts) |

Rpm value historical and trend curve analysis Batch report form analysis Keep and deliver data

|

|

|

Temperature

|

Temperature of cooling water: +5℃-65℃±0.2℃

Fermentation process control (According to the fermentation time, auto- control temperature fluent, at least10 parts) |

Temperature value historical and trend curve analysis Batch report form analysis Keep

|

|

|

Feeding

|

PID automatic enactment and control

Fermentation process control (According to the fermentation time, auto- control feeding fluent, at least10 parts) |

Feeding value historical and trend curve analysis

Feeding total dosage record Batch report form analysis keep |

|

|

Pressure

|

Manual control, instrument display

|

|

|

|

Air flux

|

Manual control, instrument display

|

||

Our Advantages

Tags :