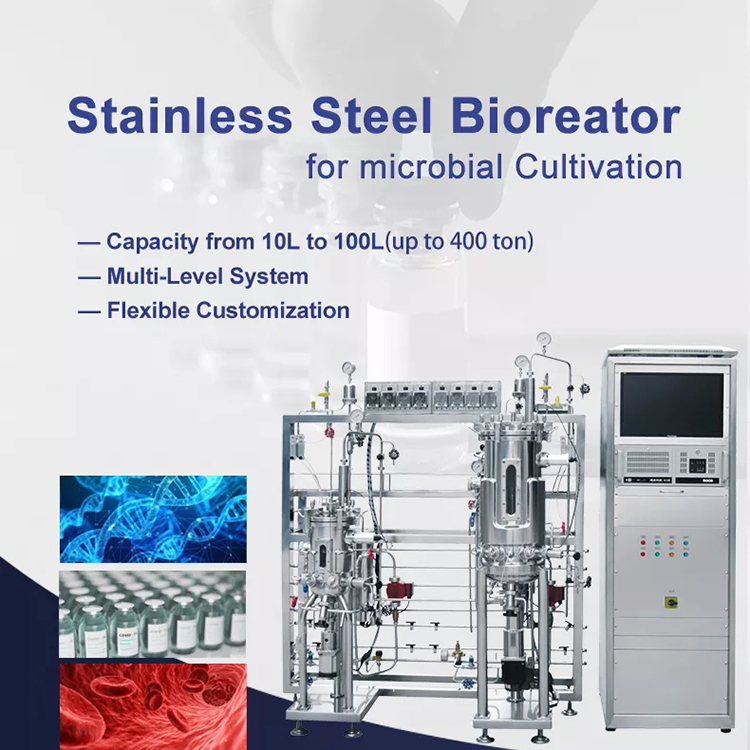

Benchtop bioreactor 100l 300l 500l 1000l 2000l 20000 100000 l 100 ton

Item no.:

OLT-500-M2Payment:

T/TProduct origin:

China

International Technology Cell Culture Bioreactor

Product Description

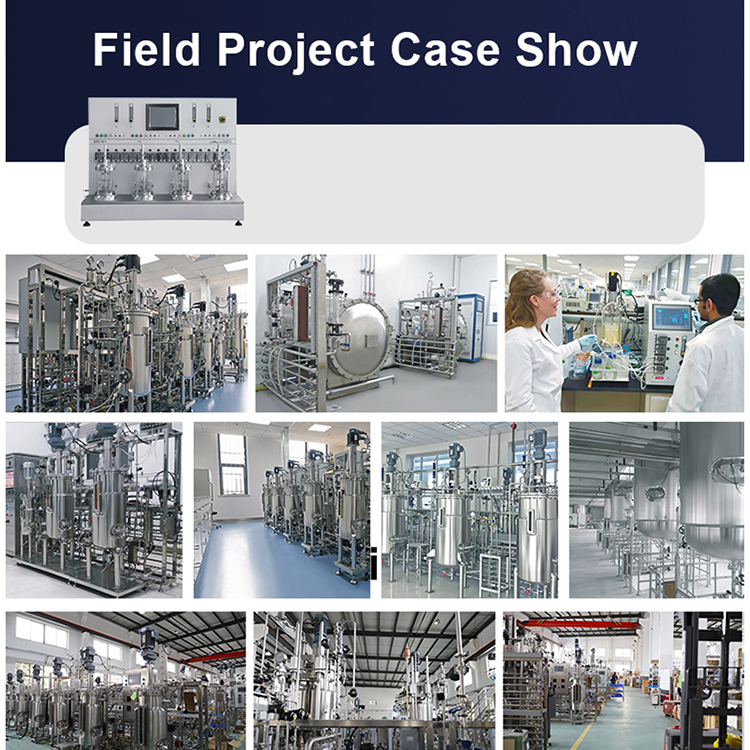

OLLITAL offers you not only with scalable range of glass and stainless steel bioreactors, but also with multi-parallel and multistep bioreactors. Based on our thorough understanding of bioreactors, rich experience for scaling up benchtop fermentors to processing system, and excellent control system for temperature, rpm, PH, DO, antifoam, feeding, aeration and pressure, you will benefit from our turnkey solution service.

Controller Technical Data

|

ontrol Unit

|

OLT-500-M2

|

|

Digital controller, colored touch screen

|

●

|

|

Control Ability

|

|

|

Temperature, DO, agitation speed

|

●

|

|

Adding acid/alkali/CO2 to control PH

|

●

|

|

Rotameter

|

●

|

|

Low noise stirring motor

|

●

|

|

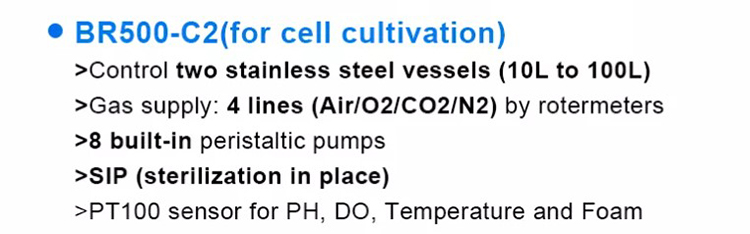

Peristaltic pump

|

8pcs

|

|

Adjusting PH (acid/alkali), deform, feeding

|

|

|

Process Data Recording

|

|

|

Temperature control

|

Process sequence control,closed loop system

|

|

Recirculating pump and heat exchanger for cooling/heating

|

|

|

PH control

|

Range: 2~12(±0.01),display: 0~14(±0.01), PID,auto control,autoweighing,system calibration

|

|

DO control

|

Range: 0~150%,±3%,International eletrode and shielded wire detection

|

|

Defoam control

|

Defoaming electrode, mechanical compression defoaming blade

|

|

Automatic foam detection, peristaltic pump automatically add defoamer in proportion to time

|

|

|

Agitation control

|

Servo motor, PID control, stepless speed regulation

|

|

Gas supply control

|

1 lines(Air/O2),Rotameter

|

|

Culture Vessel

|

|

|

PH electrode, cable

|

●

|

|

DO electrode, cable

|

●

|

|

Temperature sensor Pt 100

|

●

|

|

Foam electrode, cable

|

●

|

|

Options

|

|

|

Gas mixing options(Air、O2、CO2、N2)

|

○

|

|

Cleanliness detection

|

○

|

|

Online live cell detection

|

○

|

|

Automatic vessel pressure control

|

○

|

|

Top Aeration

|

○

|

|

TMFC (Thermal Mass Flow Controller)

|

○

|

|

CO2 detection

|

○

|

|

Redox

|

○

|

|

Exhaust detection analysis

|

○

|

|

Liquid Level

|

○

|

|

Filling weighing system

|

○

|

|

Methanol and ethanol content online detection

|

○

|

|

Additional feed pump

|

○

|

|

Variable speed pump

|

○

|

|

Upper controller

|

○

|

|

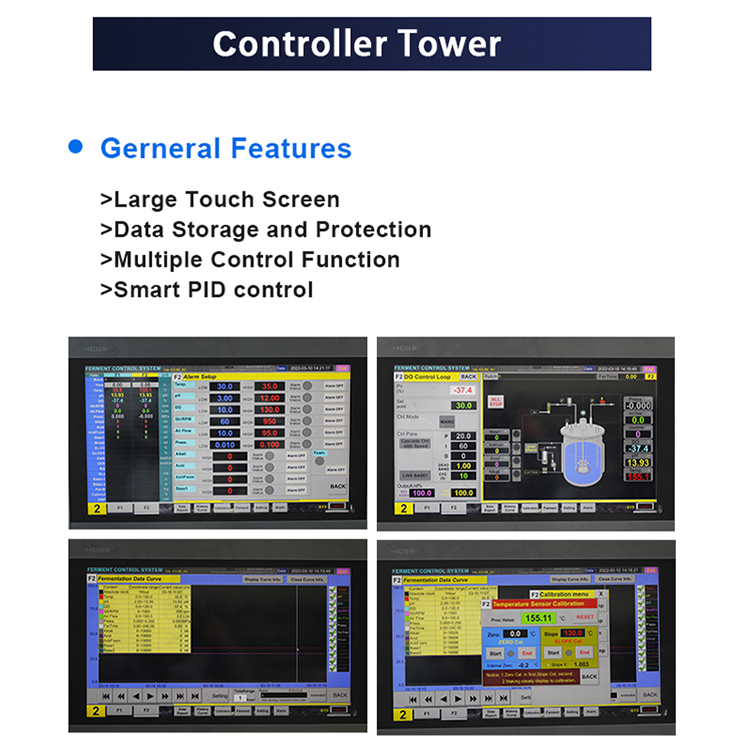

Control Tower

|

|

|

Controlling

|

Industrial PC

|

|

Display | Operation

|

Touch Panel 10“| Touch screen

|

|

Communication

|

RS485

|

|

Housing Material

|

SUS304

|

|

External Connection

|

|

|

USB

|

1pcs,Data export

|

|

Balance connection

|

2* RS485

|

|

Sensor type

|

PT100

|

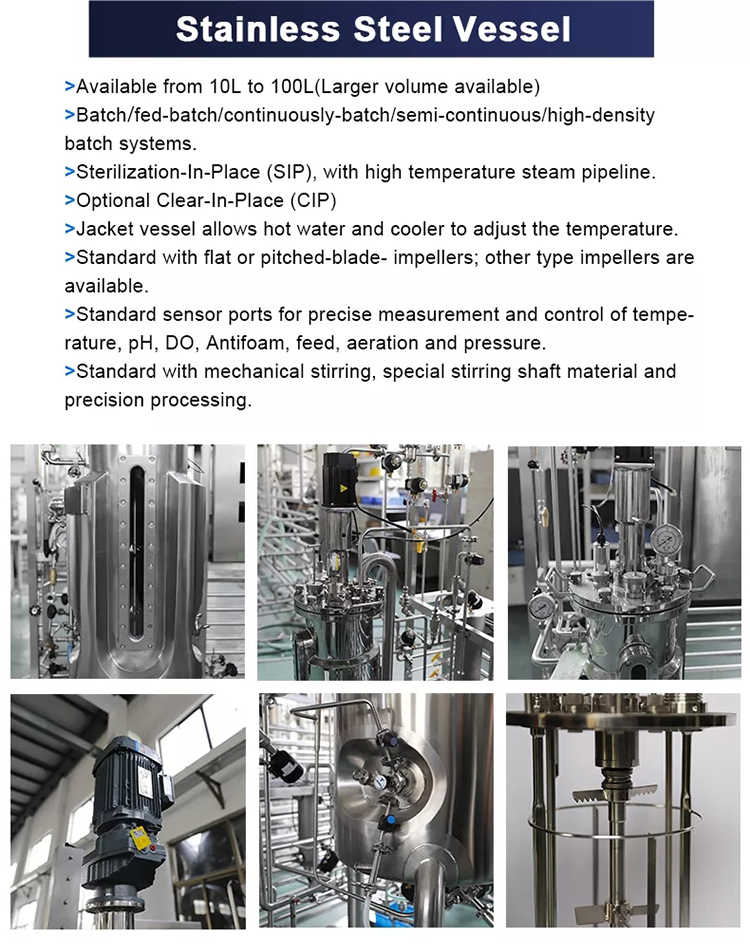

Stainless Steel Vessel Technical Data

|

Culture Vessel

|

10L

|

15L

|

20L

|

30L

|

50L

|

100L

|

|

H:D ratio

|

1:2.2~2.8

|

|||||

|

Total volume

|

13

|

18

|

27

|

34

|

58

|

132

|

|

Working volume

|

9.8L

|

13.5L

|

20.3L

|

25.5L

|

43.5L

|

99L

|

|

Minimal working volume

|

3.3L

|

4.5L

|

6.8L

|

8.5L

|

14.5L

|

33L

|

|

Agitation speed range

|

5~1000rpm

|

5~800rpm

|

5~700rpm

|

|||

|

Motorpower

|

0.75Kw

|

1Kw

|

1Kw

|

1Kw

|

0.75Kw

|

1.5Kw

|

|

Impeller to vessel diameter ratio

|

≈1:2.2~2.8

|

|||||

|

Vessel Configuration

|

|

|||||

|

Low noise stirring motor

|

●

|

|||||

|

Sterilization in place

|

●

|

|||||

|

Mechanical drive | Magnetic drive

|

● | ○

|

|||||

|

Storage bottle [2pcs]

|

●

|

|||||

|

Customizable blade

|

○

|

|||||

|

Vessel passivation

|

○

|

|||||

|

Custom port

|

○

|

|||||

|

Cover lifting

|

○

|

|||||

Cumstom Service

Our Advantages

Tags :